How do the design functions of cooling slots and expansion slots contribute to the performance and longevity of Stainless Steel Circular Saw Blades while cutting thru stainless steel substances?

Date:2024-01-18

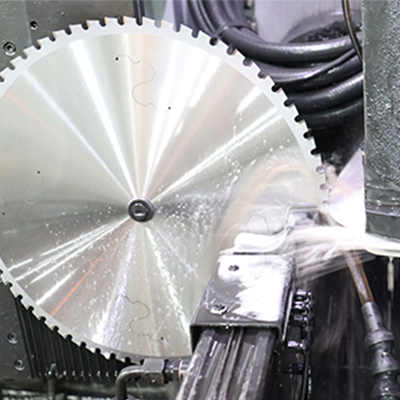

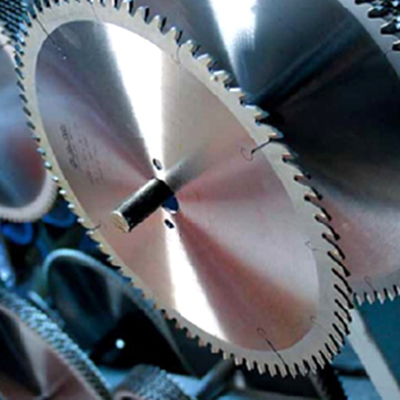

Stainless metal circular saw blades are necessary tools in various industries, specifically in steel fabrication and production, in which reducing via stainless-steel is a common and traumatic task. The design capabilities of cooling slots and expansion slots play a critical role in improving the performance and sturdiness of those specialized blades.

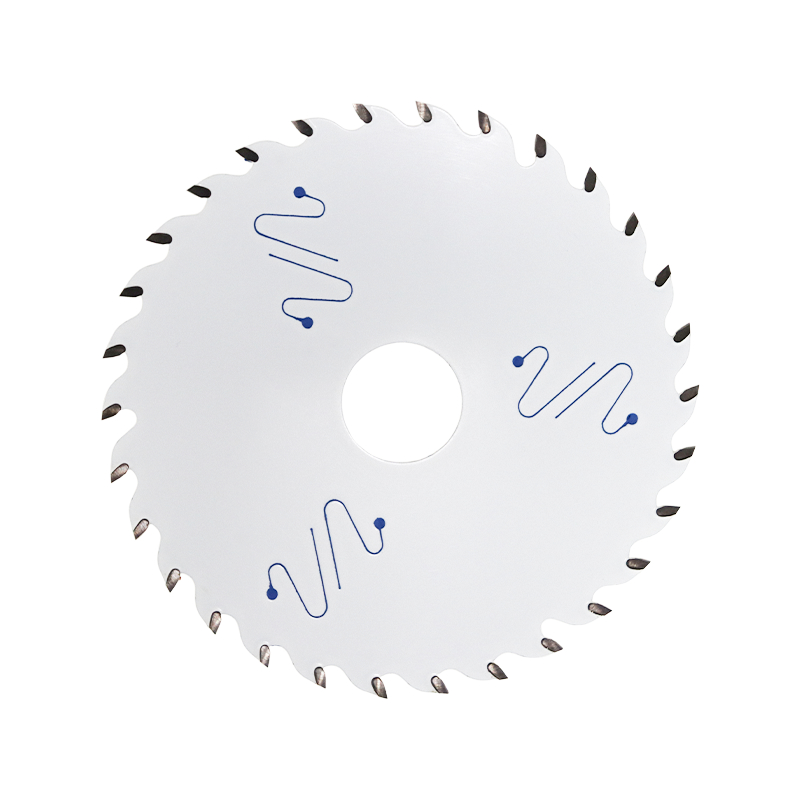

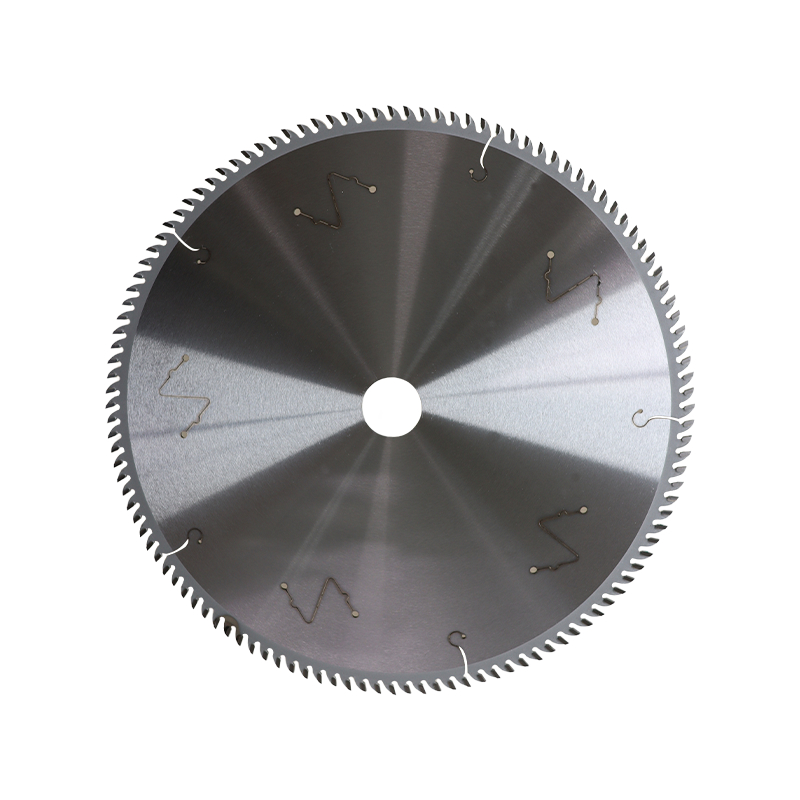

Cooling Slots:

Cooling slots, additionally referred to as gullets or vents, are strategically integrated into the design of stainless-steel circular noticed blades to deal with the significant trouble of heat buildup in the course of reducing. Stainless steel is thought for its excessive thermal conductivity, which means it could behavior and preserve heat successfully. When cutting through stainless-steel, the friction among the blade and the workpiece generates huge heat, which, if no longer controlled nicely, can result in premature blade put on, degradation, or even warping.

Cooling slots function as channels for the dissipation of warmth generated all through the slicing procedure. These slots permit air to go with the flow over and around the blade, carrying away the warmth and stopping the blade from overheating. This cooling mechanism now not simplest safeguards the integrity of the blade but additionally guarantees that the stainless steel being reduce does no longer undergo unwanted changes due to excessive warmness, such as hardening or distortion. As a end result, the cooling slots drastically make a contribution to retaining the sharpness and effectiveness of the blade over extended durations of use.

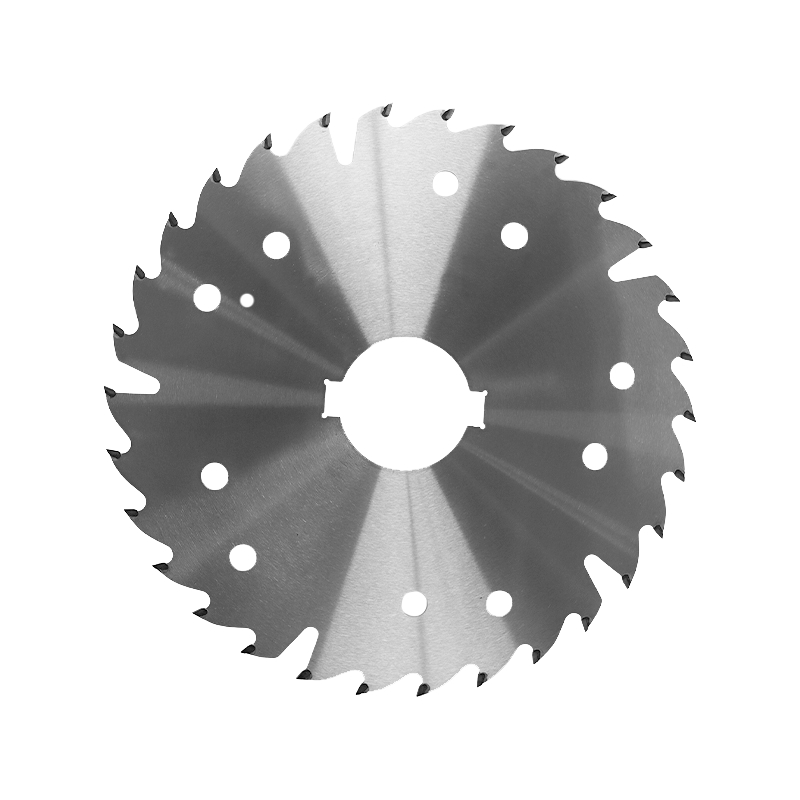

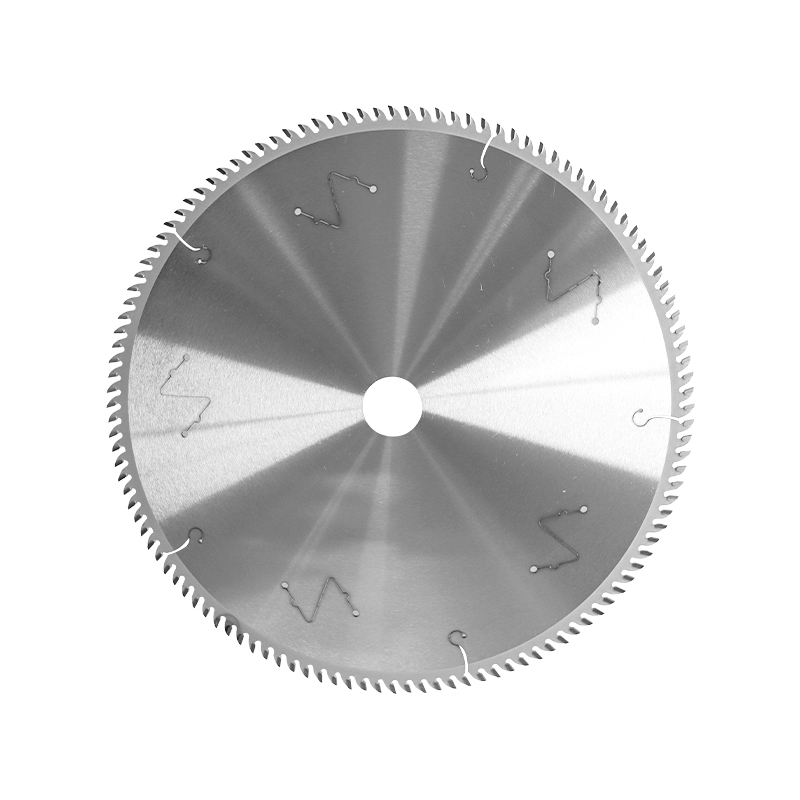

Expansion Slots:

Expansion slots, regularly precision laser-cut into the blade, serve a different yet equally important reason. Stainless steel has particular thermal growth properties, meaning it expands and contracts notably with temperature variations. During the reducing procedure, the blade is subjected to expanded temperatures because of friction, leading to thermal growth. Without right accommodation for this expansion, blades can warp or lose their straightness, resulting in misguided cuts and capacity safety dangers.

Expansion slots are strategically positioned to counteract the thermal growth of the blade. By permitting the blade to expand inside the slots without compromising its structural integrity, these capabilities help maintain the blade's alignment and ensure that it remains genuine at some stage in operation. This is particularly vital whilst precision and accuracy are paramount in programs which includes steel fabrication and creation, wherein even the slightest deviation can result in suboptimal consequences.

In summary, both cooling slots and expansion slots in stainless steel circular noticed blades make contributions drastically to their typical performance and durability. The cooling slots prevent overheating and subsequent put on, while the expansion slots accommodate thermal expansion, retaining the blade's straightness and accuracy. Manufacturers carefully engineer these features to address the particular demanding situations posed with the aid of slicing thru chrome steel, making sure that these blades meet the excessive needs of the enterprise in phrases of performance, precision, and durability. Users ought to adhere to recommended operating parameters and preservation practices to maximize the benefits of those layout factors and optimize the performance of stainless steel circular saw blades in their packages.

ZCDJ-036 High Speed Cutting Stainless Steel Circular Saw Blades

ZCDJ-036 High Speed Cutting Stainless Steel Circular Saw Blades

English

English 中文简体

中文简体