Honesty and practicality, persevering unremittingly, teamwork spirit, achieving greatness.

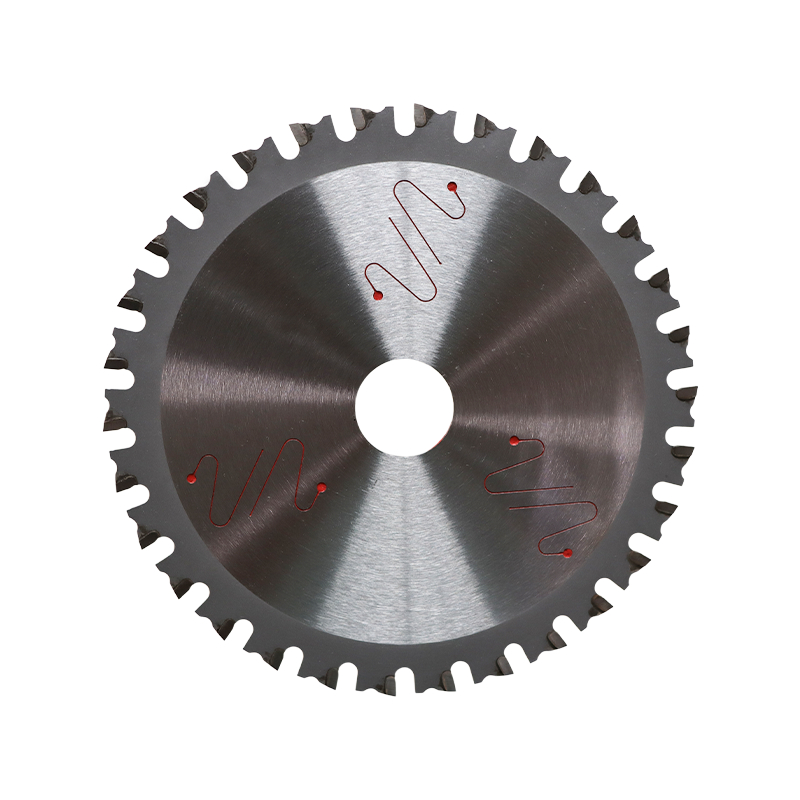

Iron Circular Saw Blades Manufacturers

About Us

Zhejiang Zhongcun Precision Cutter Machinery Co., Ltd.

Zhejiang Zhongcun Precision Cutter Machinery Co., Ltd established in 2005 in Huzhou city, which is the leader of technology innovation in China. Build up two branches in China successively: Harbin Zhongcun has advanced production process machines and manufacturing area in 24000 square meters, Huzhou Tetsuya mainly produce iron ceramic cold saw blade, dry cutting saw blade excusive to ironman, PCD diamond saw blade. Until now, we have 17 years production experience of Iron Circular Saw Blades. Our total manufacturing base area is 62000 square meters and more than 20 modernization assembly lines, annual production quantity is 3.5-4.0 million pieces. We got ISO9001 management system certification in 2015 and two patents.

Zhejiang Zhongcun Precision Cutter Machinery Co., Ltd is China Iron Circular Saw Blades Manufacturers and OEM Iron Circular Saw Blades Factory, we offer wholesale Iron Circular Saw Blades for sale online. Our tenet is innovation and development, keeping excellence as well as honesty and credibility. We have professional production department, quality control department R&D department, finance department and Sales department. So we can do OEM and ODM service for you. If you have any requirements of saw blade, we can supply all kinds of professional service for you, such as pre-production design, follow-up of progress in production, shipping arrangement and others.

Enterprise style

Corporate purposes

High standard, high precision, zero defect.

Enterprise Culture

Do not accept substandard products, do not manufacture substandard products, and do not flow out substandard products.

Haven't Found The Types You Want?

Talk to Our ExpertOUR latest news

-

In the development enterprise, how does the select...

2024-01-25In the development enterprise, how does the selection of Diamond Saw Blades with the precise Blade Diameter and Arbor Size impact reducing efficiency, safety, and universal undertaking fulfillment? I...

-

How do the design functions of cooling slots and e...

2024-01-18Stainless metal circular saw blades are necessary tools in various industries, specifically in steel fabrication and production, in which reducing via stainless-steel is a common and traumatic task. T...

-

How does the kerf size of a Panel Saw Wood Circula...

2024-01-11How does the kerf size of a Panel Saw Wood Circular Saw Blade effect woodworking performance, material waste, and average slicing overall performance? The kerf size of a Panel Saw Wood Circular Saw B...

English

English 中文简体

中文简体