How does the kerf size of a Panel Saw Wood Circular Saw Blade effect woodworking performance

Date:2024-01-11

How does the kerf size of a Panel Saw Wood Circular Saw Blade effect woodworking performance, material waste, and average slicing overall performance?

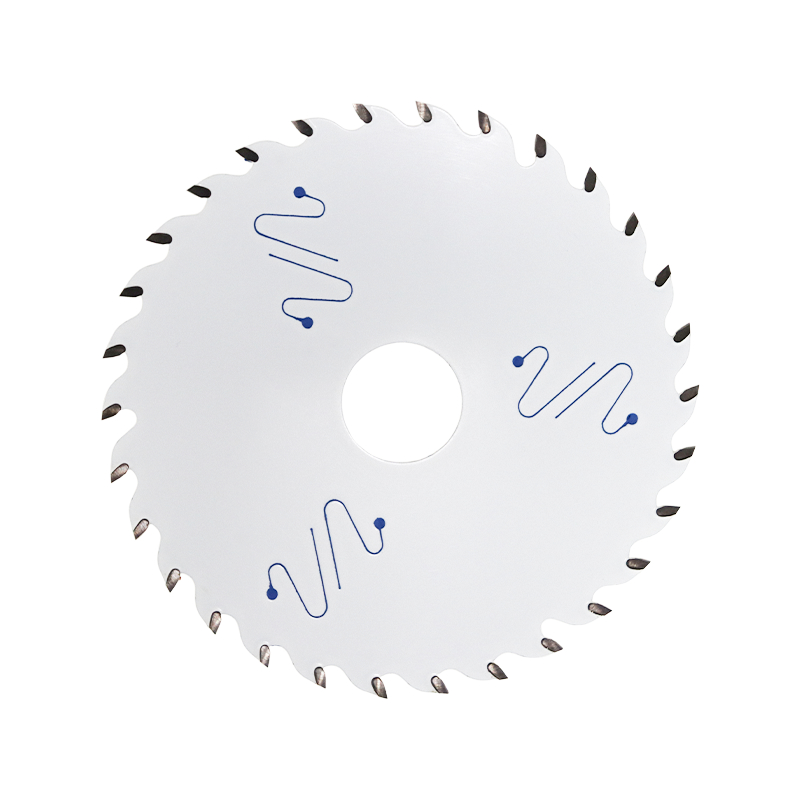

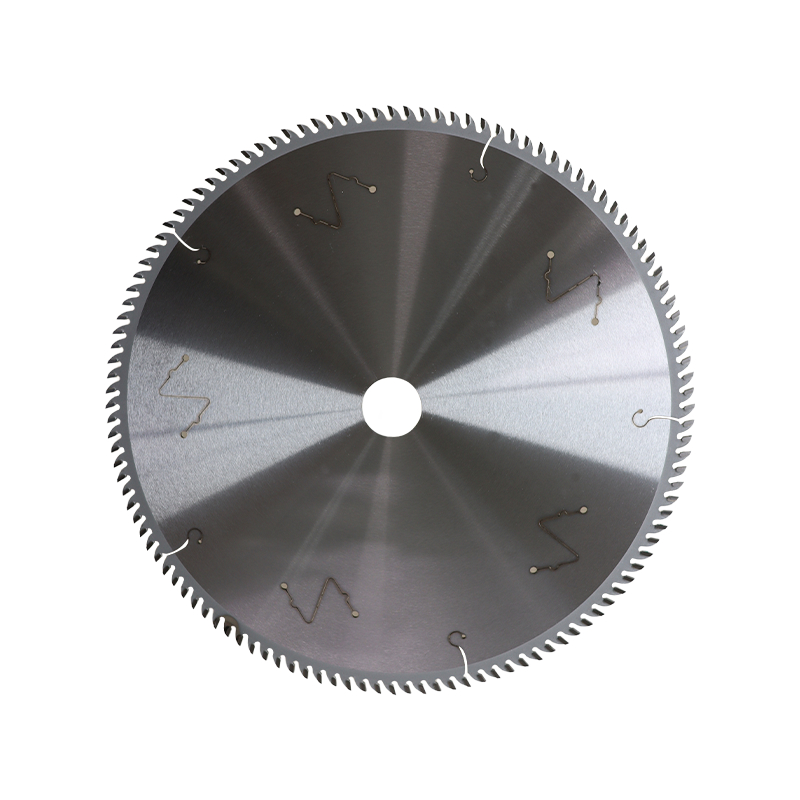

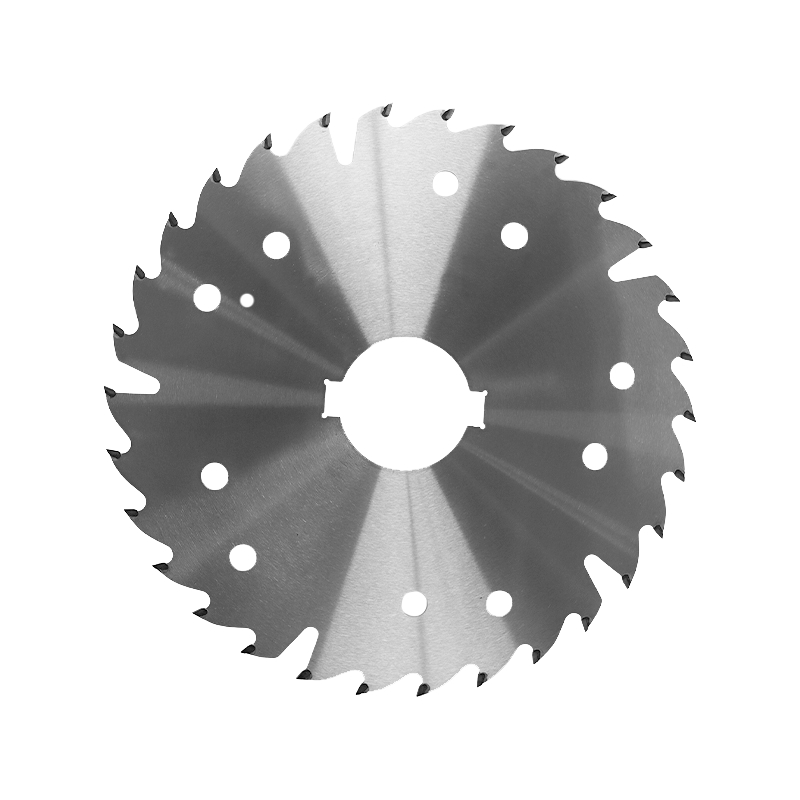

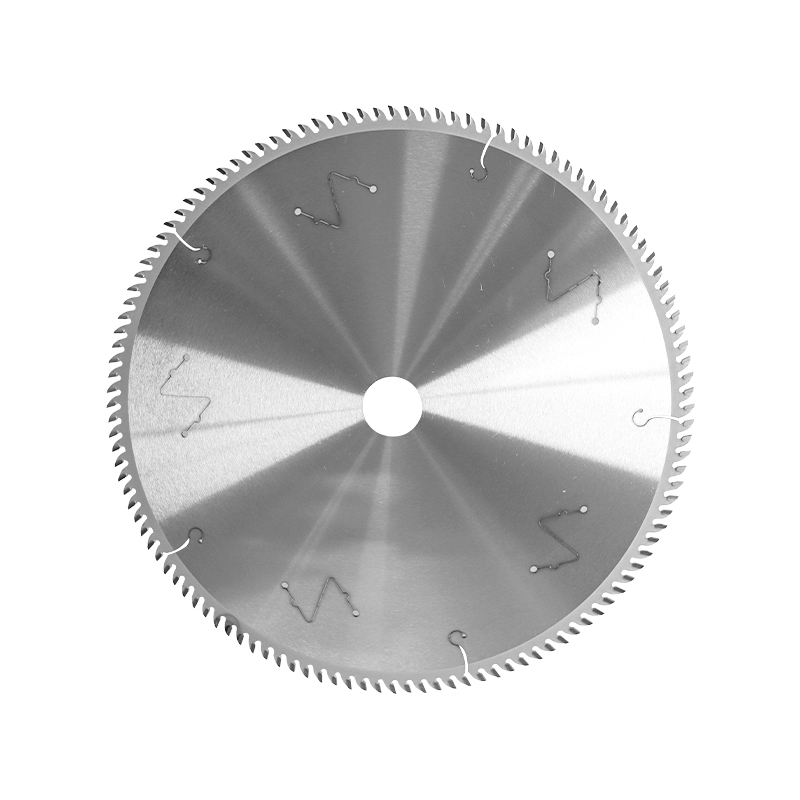

The kerf size of a Panel Saw Wood Circular Saw Blade plays a essential position in figuring out various aspects of woodworking, which includes performance, cloth waste, and general slicing overall performance. The term kerf refers to the width of the reduce made by way of the noticed blade, and understanding its importance is essential for optimizing the performance of panel saws in exceptional programs.

Efficiency:

The kerf length at once impacts the performance of the cutting manner. A thinner kerf removes less cloth in the course of each skip, resulting in decreased resistance and strength consumption. This can be specifically effective in terms of performance, specially while working with lower-powered panel saws. The decreased attempt required for each reduce allows for smoother and more green operation, contributing to increased productivity in woodworking tasks.

Material Waste:

The kerf size has a sizable effect on cloth waste. A thinner kerf removes a smaller amount of cloth with every reduce, translating to much less wasted material. This is in particular essential when working with costly wood or when aiming to maximize the yield from a given stock. Woodworkers often are seeking for to decrease cloth waste to decorate cost-effectiveness, and deciding on a blade with the appropriate kerf length is a strategic selection in accomplishing this goal.

Power Consumption:

Thinner kerf blades commonly require less strength to pressure via the fabric. This is positive for panel saws with decrease horsepower rankings, as the decreased electricity demand lets in for smoother operation and extends the lifespan of the saw's motor. Woodworking shops with varying energy capacities can advantage from choosing blades with kerf sizes that healthy the competencies in their device, ensuring premier overall performance with out straining the equipment.

Cutting Precision:

The kerf length impacts reducing precision, in particular in programs wherein first-class detail and accuracy are critical. A thinner kerf produces a narrower cut, making an allowance for extra specific cuts in complicated woodworking tasks. This is especially essential while developing joinery or when the mission needs tight tolerances. Conversely, a thicker kerf may additionally offer extra stability, which can be positive whilst slicing thru dense or challenging substances.

Chip Removal and Heat Dissipation:

The kerf length affects chip elimination and heat dissipation throughout the slicing manner. Thinner kerfs generate smaller chips, which might be less difficult to evacuate from the cutting area. Additionally, the decreased amount of material being reduce effects in much less friction and heat buildup. Proper chip elimination and warmth dissipation make a contribution to the longevity of the blade, preventing premature wear and ensuring regular slicing overall performance over the years.

In conclusion, deciding on the proper kerf length for a Panel Saw Wood Circular Saw Blade is a essential decision that affects numerous factors of woodworking. Woodworkers should cautiously do not forget the precise necessities in their initiatives, the sort of cloth being reduce, and the talents in their panel saws. By choosing the choicest kerf length, woodworkers can enhance efficiency, decrease material waste, and obtain the desired level of cutting precision in their woodworking endeavors.

ZCDJ-005 TCT Durable Woodworking Circular Saw Blades

ZCDJ-005 TCT Durable Woodworking Circular Saw Blades

English

English 中文简体

中文简体