Aluminum Alloy Saw Blades are used in a variety of applications

Date:2023-06-22

Choosing Aluminum Alloy Saw Blades

Aluminum Alloy Saw Blades are used in a variety of applications, from woodworking to metal cutting. Their use has increased dramatically over the years as technology has improved. Whether you’re an industrial contractor or a homeowner, you may need these saw blades for your next project.

There are many things to consider when choosing the right blade for your needs, and it’s important to know what makes up a good blade before you buy one. Here are some of the key features to look out for:

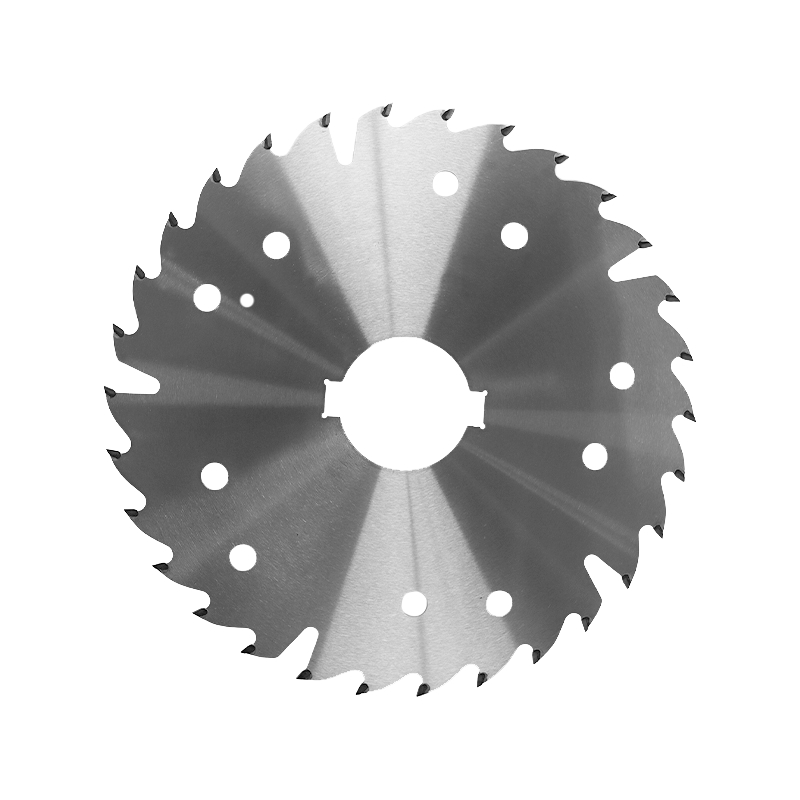

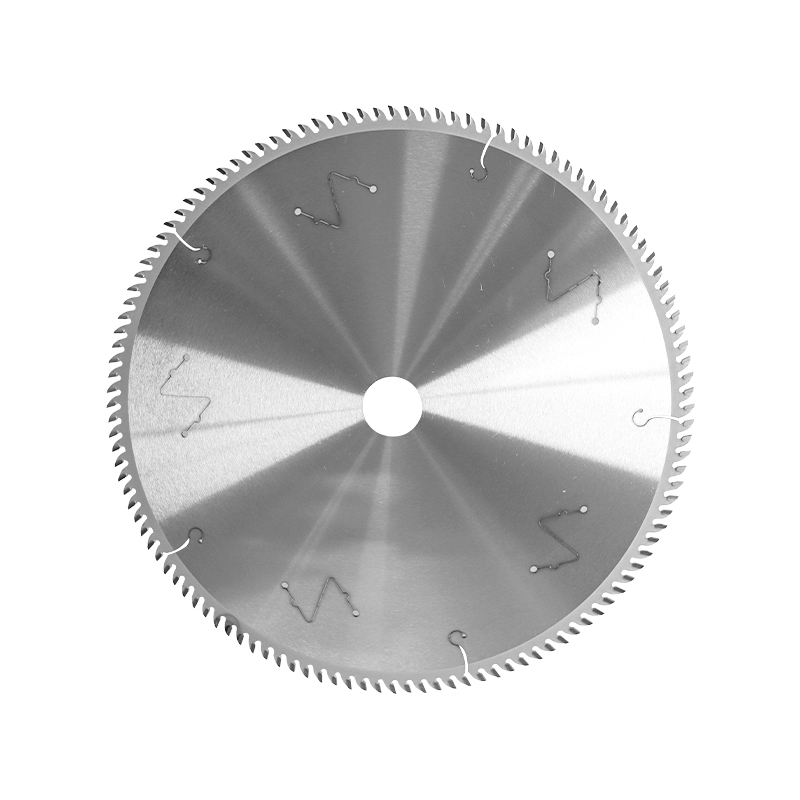

The number of teeth

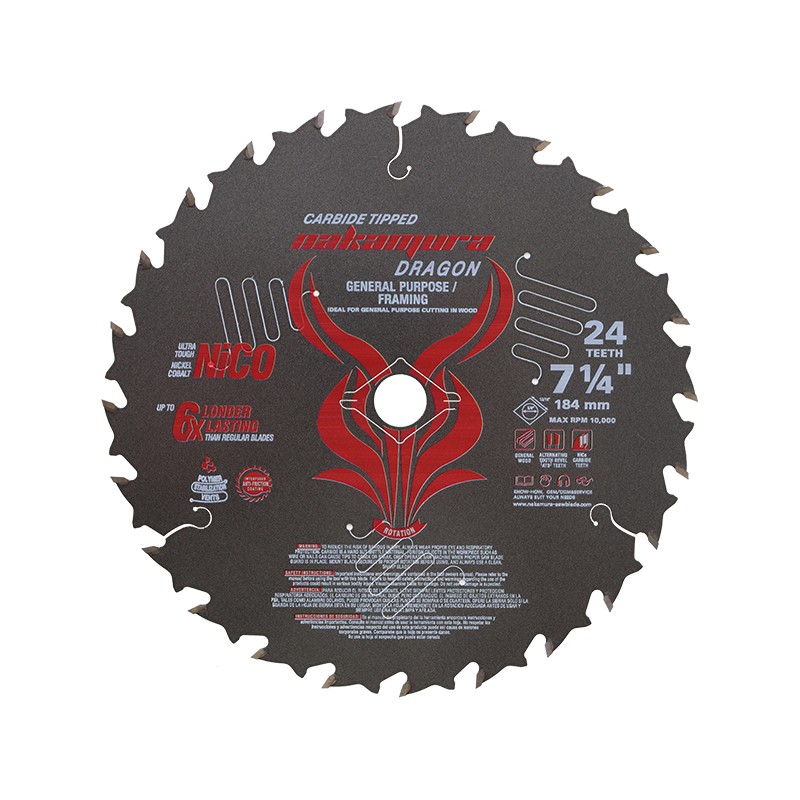

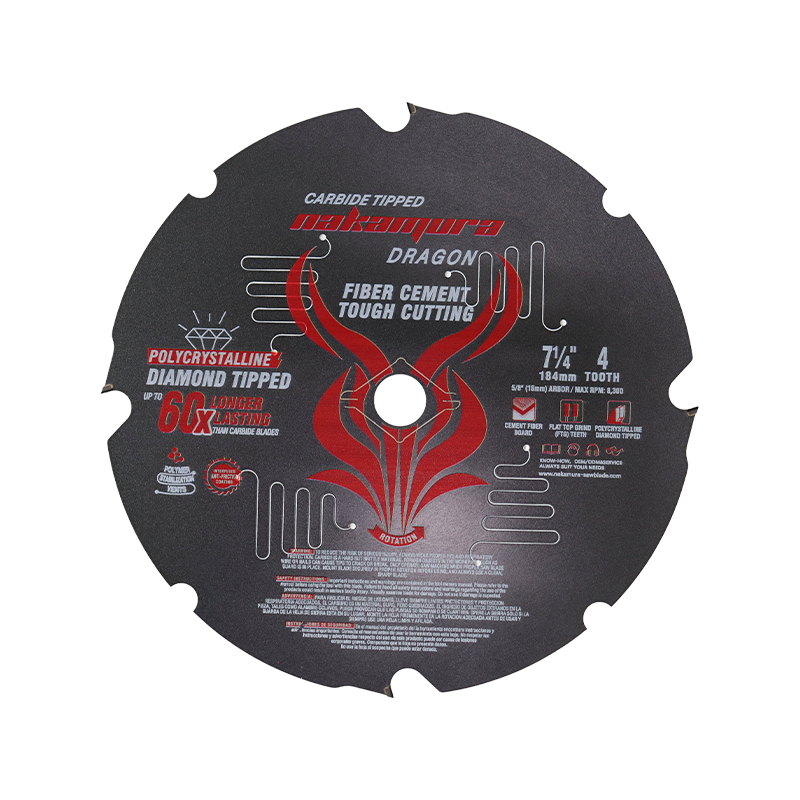

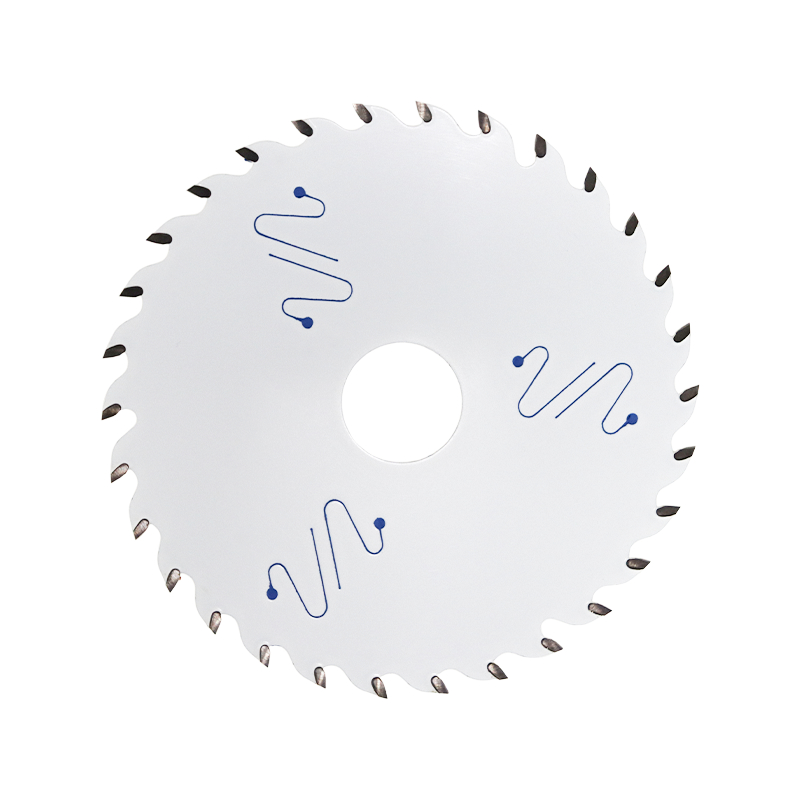

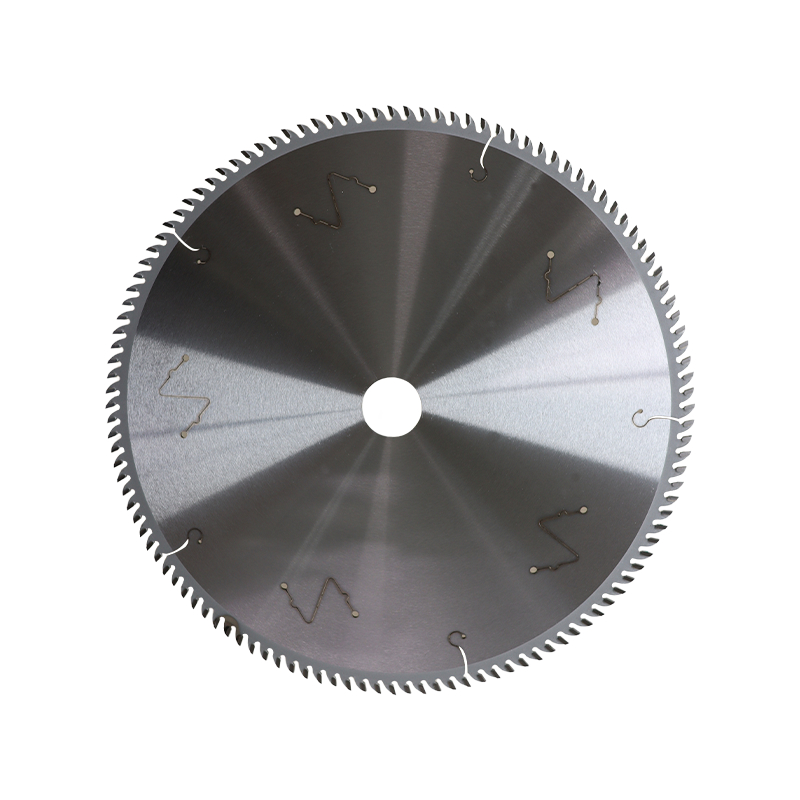

The more teeth a blade has, the cleaner it cuts; however, this also means that it can be slowed down by the sheer number of teeth. So if you’re looking to cut through large amounts of wood, it may be worth going with a thinner blade - 30 teeth instead of 48 for example.

Tooth Angle

The angle of a tooth is an important consideration when choosing a blade – it affects how sharp it is and how effectively the blade cuts through the material. It’s important to choose a blade that has a good angle because it will give you a better, more consistent cut.

Bevels

The bevel of a blade is an important consideration, too. It helps to ensure that there is a really sharp point in contact with the timber at all times. This is important when cutting through long strands of timber, as it will keep the rip line sharp and prevent tear-out.

Gullet size

Ripping blades have a much larger gullet than cross-cut blades. This is because they’re designed to chop through long strands of wood, so they need a bigger gullet to allow the big chips to clear.

Using a saw with a poor-quality blade can lead to serious problems. First and foremost, a bad blade will cause galling on the surface of the workpiece, which can make it difficult to get a clean, smooth finish. It can also cause the blade to wear out quickly.

Second, a bad blade will have poor cut accuracy and can cause saw marks to appear. This can be a real problem, especially on softwood or hardwood.

Third, a good blade will have engineered expansion slots (those little fish-hook holes in the blade face). They reduce blade noise, help to maintain the shape of the blade, and can prevent warping under heat.

Fourth, a good blade will be designed with an adjustable blade angle. This is a great feature for people who are new to woodworking and need to learn how to adjust the angle of their blades or those who need to cut a range of different materials.

A good quality saw blade will come with a set of screws for adjusting the blade angle, and these can be adjusted to a wide range of angles. The adjustments are easy to do and will keep your blades performing well for a very long time.

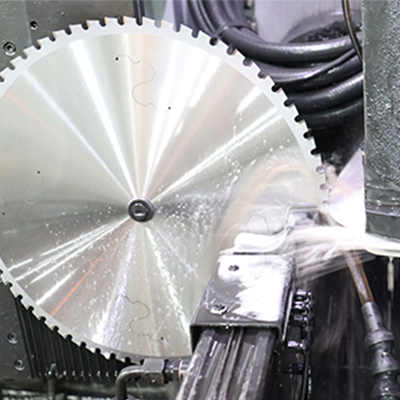

ZCDJ-040 Ferrous Metal Cutting Circular Tungsten Carbide Tipped Saw Blade

Nakamura Logo or customization.

Teflon Surface, DIAMETER is 355mm.

Package is white inner box or blister or sleeve tube and plastic bage.

Material: 75Cr1.

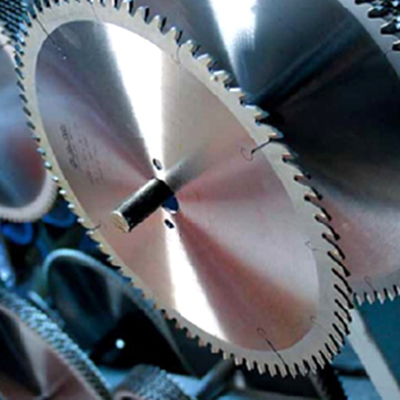

Teeth: 66Teeth (OKE Brand)

Arbor:15.88mm, 20mm, 25.4mm, 30mm or customized.

Application: Ferrous Metal, Iron and so on.

English

English 中文简体

中文简体