Precautions For Aluminum Alloy Circular Saw Blades

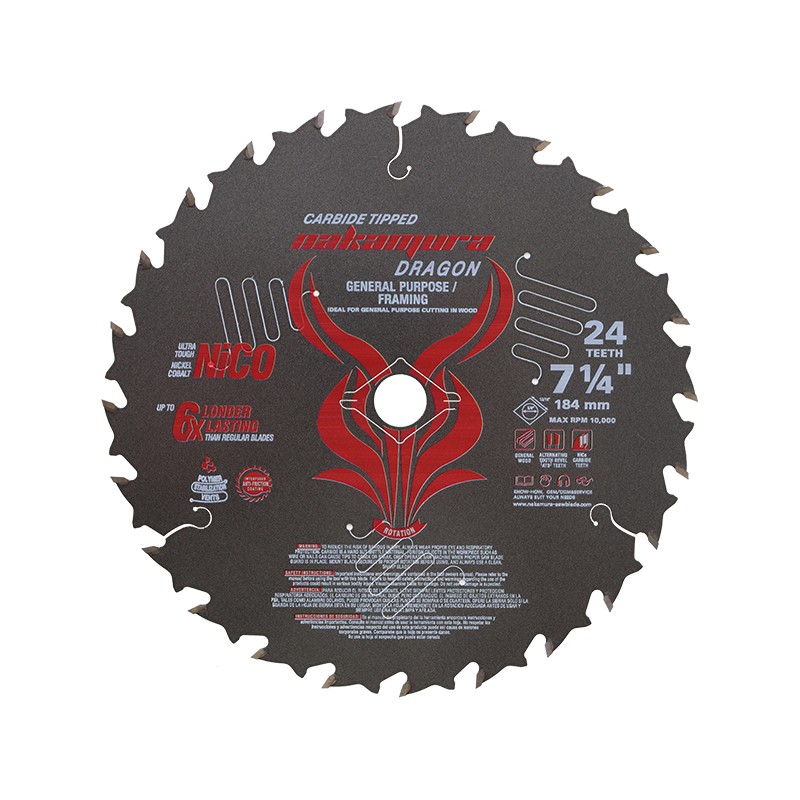

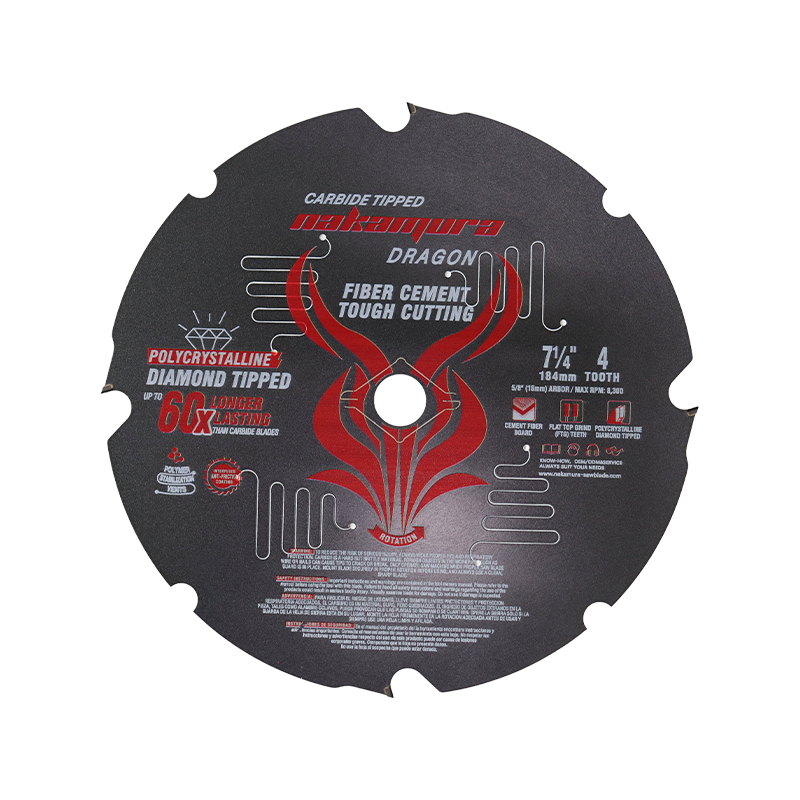

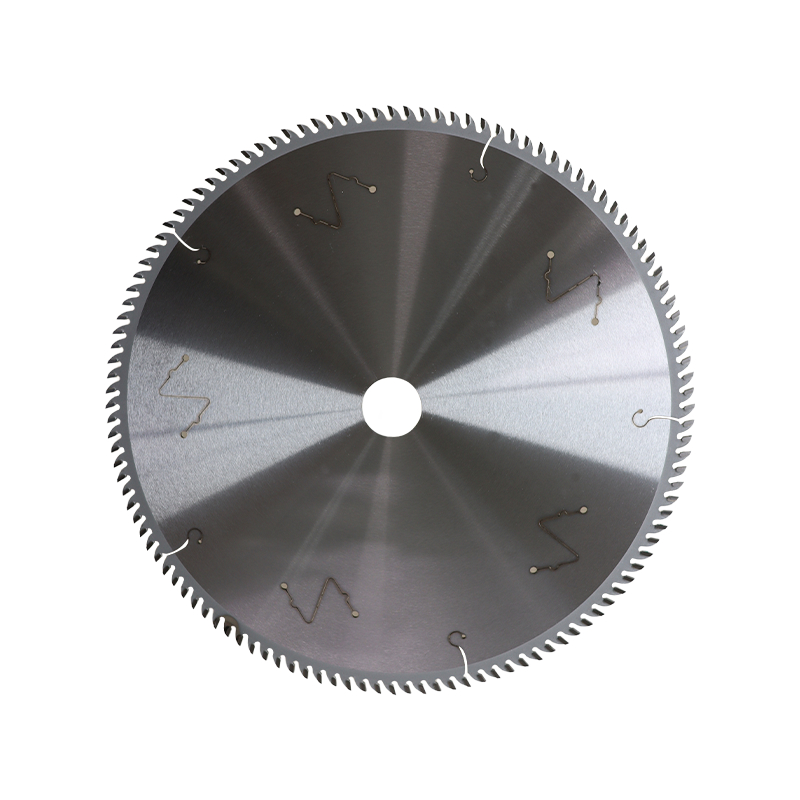

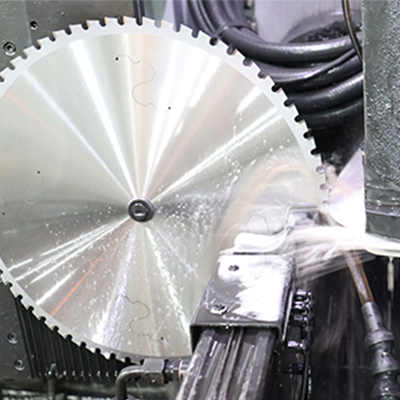

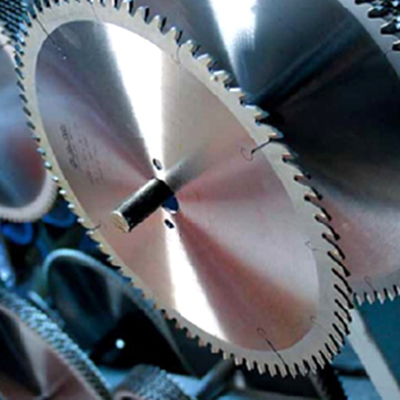

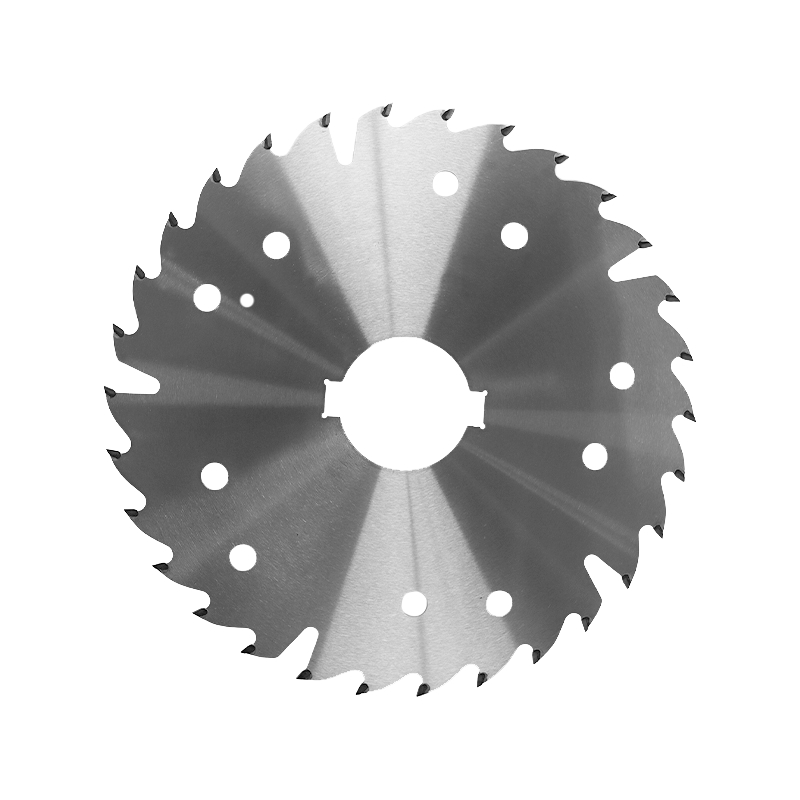

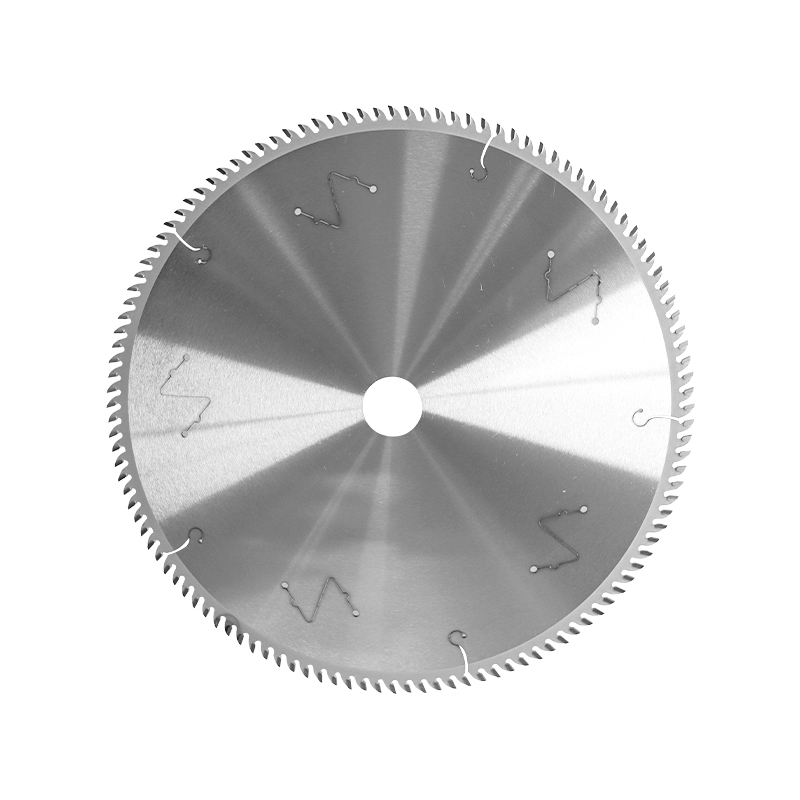

Aluminum alloy circular saw blades are specially designed for carbide insert circular saw blades for aluminum alloy material blanking, sawing, groove milling and groove cutting. Non-ferrous metals and various aluminum alloy profiles, aluminum pipes, aluminum bars, door and window materials, radiators, etc.

Notes

1. The machine should have good performance and no vibration.

2. The outer diameter of the flange should be the same, about 1/3 of the diameter of the saw blade.

3. The surface of the flange in contact with the saw blade should be perpendicular to the center line of the hole.

4. Both ends of the gasket should be parallel and perpendicular to the centerline of the hole.

5. The straightness and runout of the saw spindle must not exceed the tolerance (0.03)

6. The saw blade should be wiped clean before installation. If there is resin on the saw blade, it needs to be wiped with thinner

7. When the saw blade is dull, it should be repaired in time, and attention should be paid to maintaining the original cutting angle of the saw blade

8. When grinding, choose a suitable diamond grinding wheel, and use coolant at the same time.

9. It is recommended that the reaming of the saw blade should not exceed 20MM of the original hole, otherwise the processing effect will be affected.

10. Each installation must keep the flange and gasket clean and flat.

11. Be careful when grinding the back angle and saw body. Do not do it by hand, it will cause the sawtooth to break and the saw body to be unbalanced.

12. Before cutting, check whether the saw blade is installed and tightened to prevent displacement and slippage.

13. Hang the saw blade vertically on a dry rack and lay it back flat to cause the saw blade to deform.

14. Do not exceed the specified maximum speed during use. (The maximum speed is about 4200, and the domestic machine is about 2500)

15. When installing, first confirm the performance and use of the saw table to avoid accidents.

16. When installing, check the saw blade for cracks, bending, tooth loss, etc.

17. After the saw blade is installed, it must be confirmed whether the center hole of the saw blade is firmly fixed on the flange of the saw table, and then gently push the saw blade by hand to confirm whether the saw blade rotates eccentrically.

18. The cutting direction indicated by the arrow of the saw blade must be aligned with the rotation direction of the saw table. It is strictly forbidden to install and place it in the opposite direction, which will cause the saw blade to drop teeth.

19. Let the saw blade pre-rotate for one minute before use before cutting.

20. Reversing is prohibited. Reversing will lead to tooth loss, and it will be dangerous in serious cases.

21. An abnormal sound is heard during use. If you see abnormal shaking and uneven cutting surface, please stop working immediately, find the cause of the abnormality, or replace the saw blade.

22. When cutting, it is forbidden to stop the saw blade suddenly in the middle of the object to be cut, which will cause the sawtooth to fall off or the saw blade to deform.

23. Please wipe the anti-rust oil in time after cutting to prevent the saw blade from rusting.

24. To grind the serrations when the serrations are not sharp, they must be ground by a grinding agency designated by the manufacturer or a shop with grinding technology.

Zhejiang Zhongcun Precision Cutter Machinery Co., Ltd. is a professional saw blades manufacturers, if you want to know more, please click the official website to contact us, we are willing to answer more questions for you

English

English 中文简体

中文简体