How to sharpen circular saw blades fast and well?

Date:2022-08-08

Grinding saw blades mainly use the back of the grinding teeth and the front of the grinding teeth as the pavement. When the grinding tool moves back and forth, keep the working surface of the grinding tool moving in parallel.

1. The sharpening is mainly based on the back of the tooth and the front of the tooth as the pavement, and the flank of the tooth is not sharpened without special requirements.

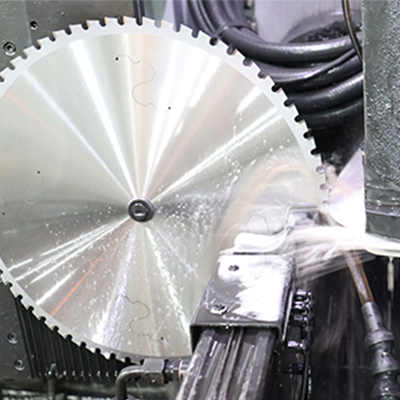

2. After sharpening, the condition that the front and rear angles remain unchanged is: the angle between the working surface of the grinding wheel and the front and rear tooth surfaces to be sharpened is equal to the grinding angle, and the distance the grinding wheel moves is equal to the grinding amount. Make the working surface of the grinding wheel parallel to the tooth surface to be ground, then touch it lightly, and then make the working surface of the grinding wheel leave the tooth surface, then adjust the working surface angle of the grinding wheel according to the sharpening angle, and finally make the working surface of the grinding wheel and the tooth surface touch.

3. The grinding depth is 0.01-0.05 mm during rough grinding; the recommended feed rate is 1-2 m/min.

4. Manual fine grinding of the saw teeth. After the tooth blade has a small amount of wear and chipping and the saw tooth is ground with a silicon chloride grinding wheel, when grinding is still required, the saw tooth can be finely ground with a hand grinder to make the tooth blade sharper. When fine grinding, the force should be uniform, and the working surface of the abrasive tool should be moved in parallel when the abrasive tool moves back and forth. Grind the same amount to ensure all tooth tips are in the same plane.

Notes on sharpening saw blades:

1. Resin, debris and other debris adhering to the saw blade must be removed before grinding.

2. Grinding should be carried out strictly according to the original geometric design angle of the saw blade to avoid damage to the tool due to improper grinding. After grinding, it can only be put into use after passing the inspection to avoid personal injury.

3. If manual sharpening equipment is used, a precise limit device is required, and the tooth surface and tooth top of the saw blade are detected.

4. When grinding, special coolant should be used to lubricate and cool during sharpening, otherwise it will reduce the service life of the tool and even cause internal cracking of the alloy cutter head, resulting in dangerous use.

English

English 中文简体

中文简体