Metal Saw Blades Are Used For Several Different Types of Metal

Date:2023-05-24

Metal Saw Blades Are Used For Several Different Types of Metal

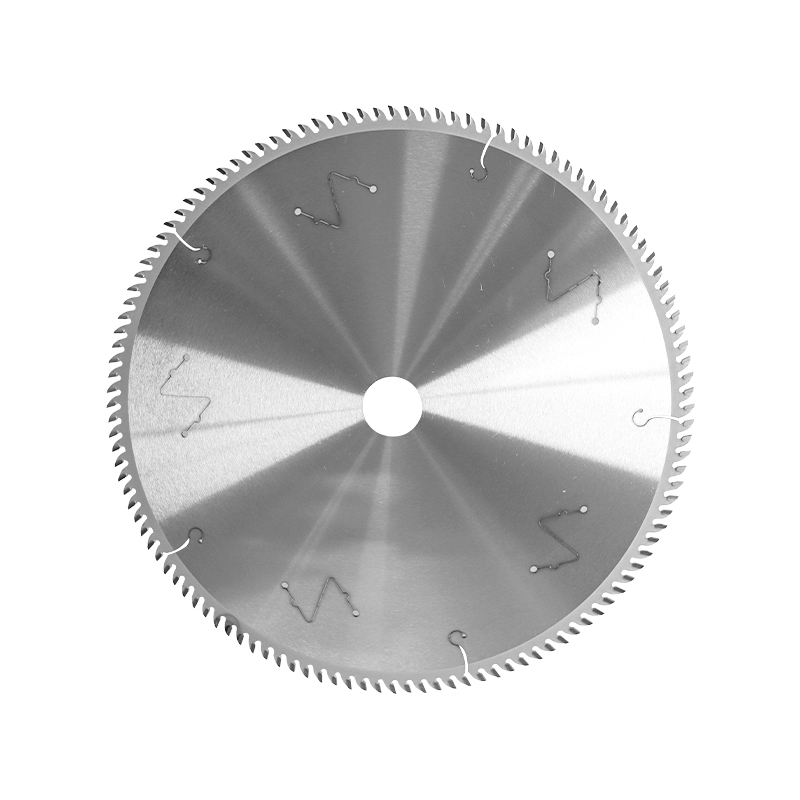

Circular saw blades are used to cut a variety of materials including steel, wood, and other types of metal. They come in a wide variety of shapes and sizes. The best ones are designed to meet your specific needs and make the job easier for you.

The first step in selecting the perfect metal circular saw blade is to consider what type of material you plan on cutting and what thickness it will be. You may also need to consider the length and width of the blade. This will ensure you choose the one that fits your needs.

Typically, you'll want a blade that's wide enough to cut through your metal and thin enough to fit within the tolerances of the material. Choosing the right size will also save you time and money.

If you plan on cutting thin sheet metal, you'll need a blade with more teeth and a tooth configuration that will not grab and tear the material but will be able to act like a "sheet metal nibbler." This Irwin metal blade is designed with those characteristics in mind.

The blade is also made from a construction-grade titanium carbide that allows it to tackle a wide variety of metals and materials, including aluminum, brass, bronze, copper, plexiglass, and plastic. This blade is an ideal choice for both professional and home projects.

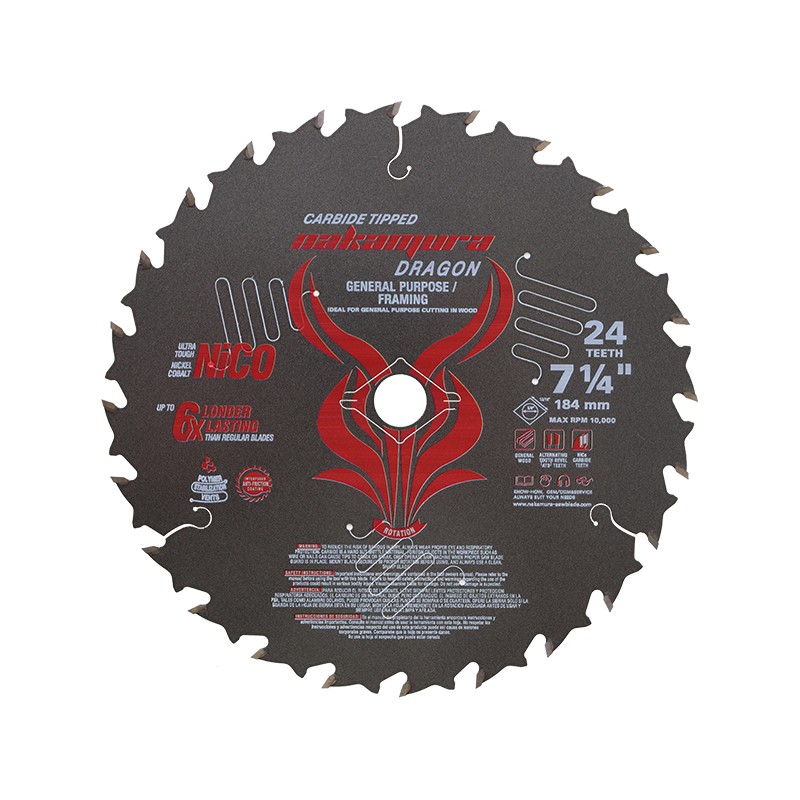

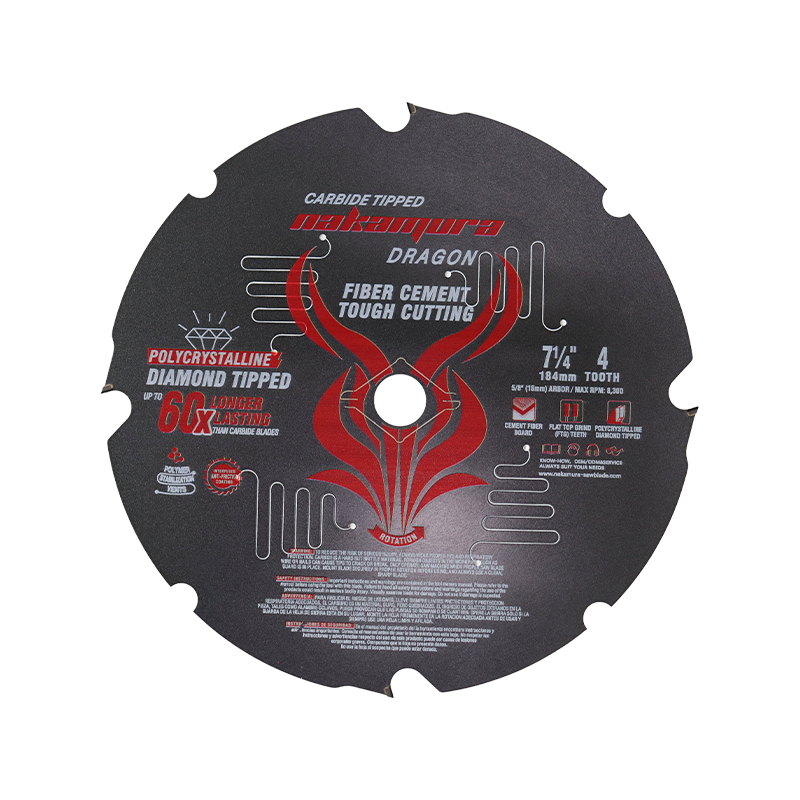

Carbide-Tipped Band Saw Blades Are The Most Popular

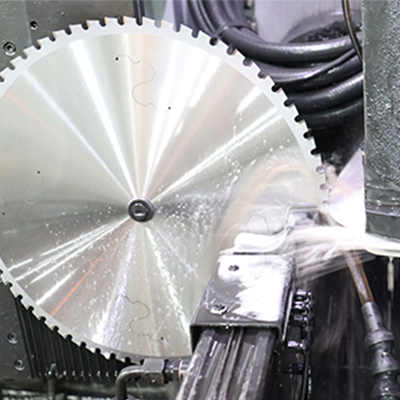

The carbide-tipped saw blade is one of the most popular choices among metal circular saw blades because it offers a number of benefits to metalworking operations. These include improved speed and feed rate, reduced downtime due to blade failure, improved surface finish, and increased tool life.

A carbide-tipped saw blade has a hardened edge and is crafted from high-carbon steel that is welded to an alloy backing. This combination of materials provides superior strength and durability for tough jobs.

These blades are a great option for cutting 2X lumber, wood with nails, channels, flat bars, steel studs, and threaded rods. They also offer excellent impact resistance, making them the ideal blade for a variety of metalworking applications.

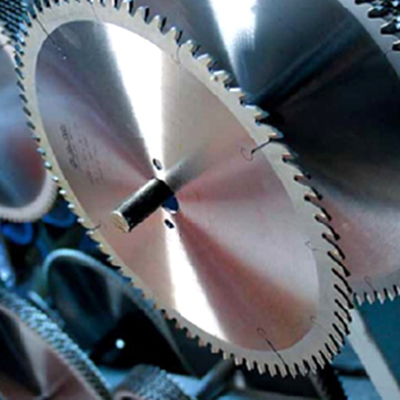

Bi-metal Circular Saw Blades Are The Most Durable

Unlike carbon blades, bi-metal blades are made from two dissimilar metals. They are welded to a hardened, high-strength alloy backing. These blades often contain 8% cobalt to provide extreme wear characteristics and resist corrosion.

They are available in a variety of lengths, widths, and thicknesses and usually last much longer than carbon blades. This is because they are designed to withstand more wear and tear than typical carbon blades.

The lifespan of the blade can be affected by several factors, including how often it's used and what kind of metal it is cutting. You should also think about the type of machine it's on and what the speed is.

You'll also want to look at the angle of the blade's hook (or claw shape). The hook can be very aggressive, particularly for wood cutting. But when you're cutting steel, the angle is usually just 1 degree or less, which is more than sufficient to hold down the workpiece as the blade cuts it.

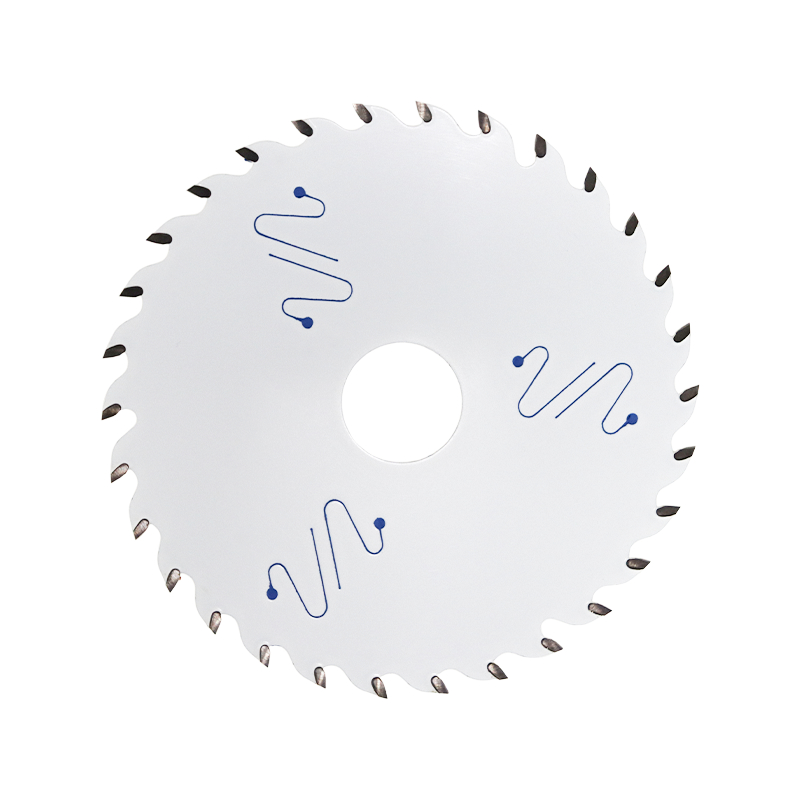

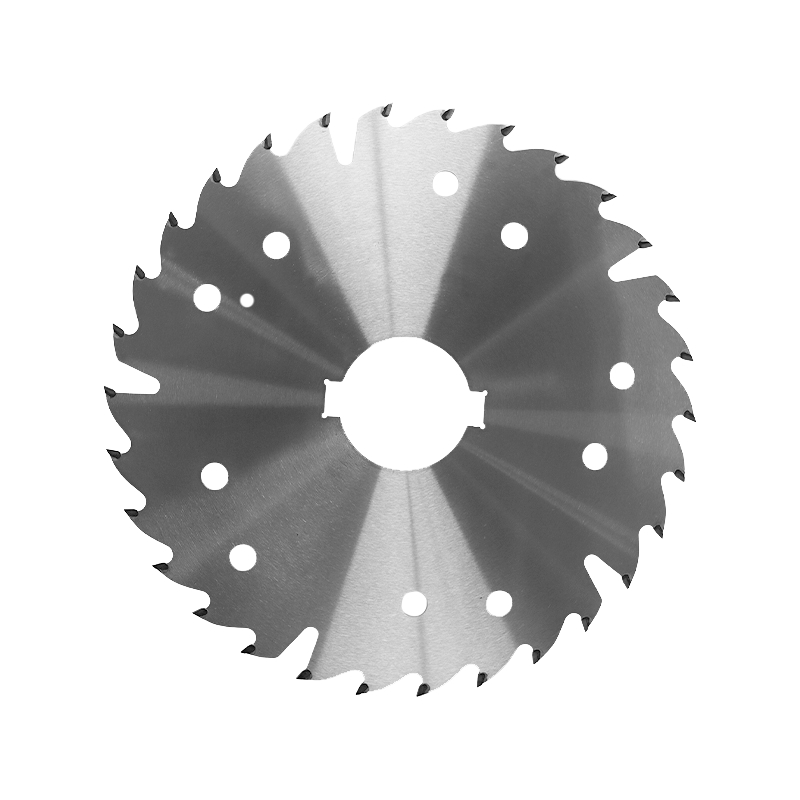

ZCDJ-005 TCT Durable Woodworking Circular Saw Blades

Nakamura Logo or Customization.

Teflon Surface, DIAMETER is 165mm.

Package is white inner box or blister or sleeve tube and plastic bage.

Material: 75Cr1.

Teeth: 40Teeth(OKE).

Arbor:15.88mm, 20mm, 25.4mm, 30mm or customized.

Application: Crosscutting of hardwood and softwood and precise cutting of plywood, clamp plate, density board and core block board.

High efficiency and low noise wordworking saw.

English

English 中文简体

中文简体