PCD Circular Saw Blades are designed to cut hard materials that would otherwise be difficult to machine

Date:2023-06-01

PCD Circular Saw Blades

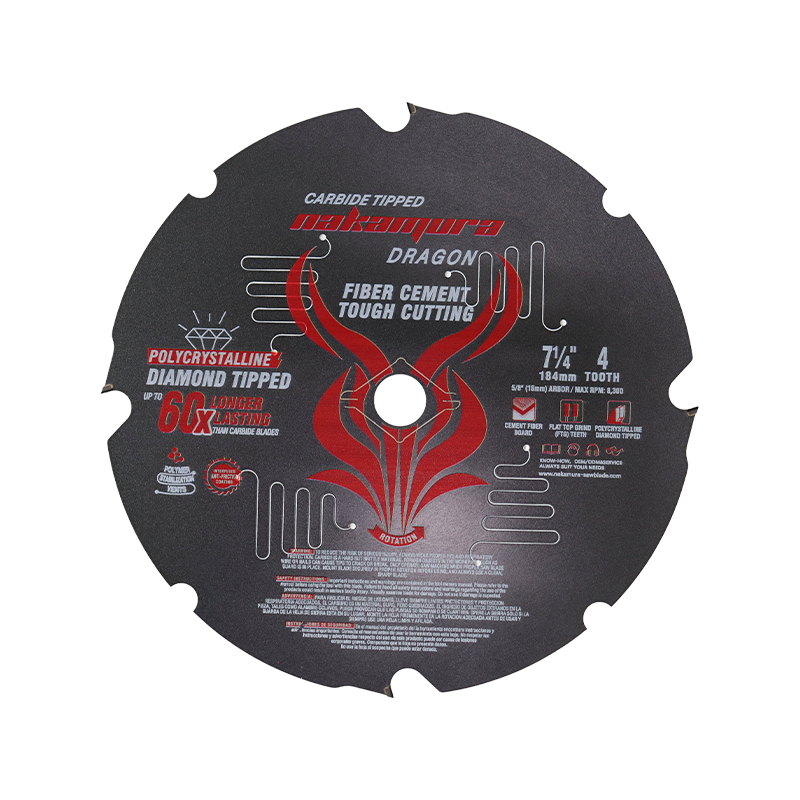

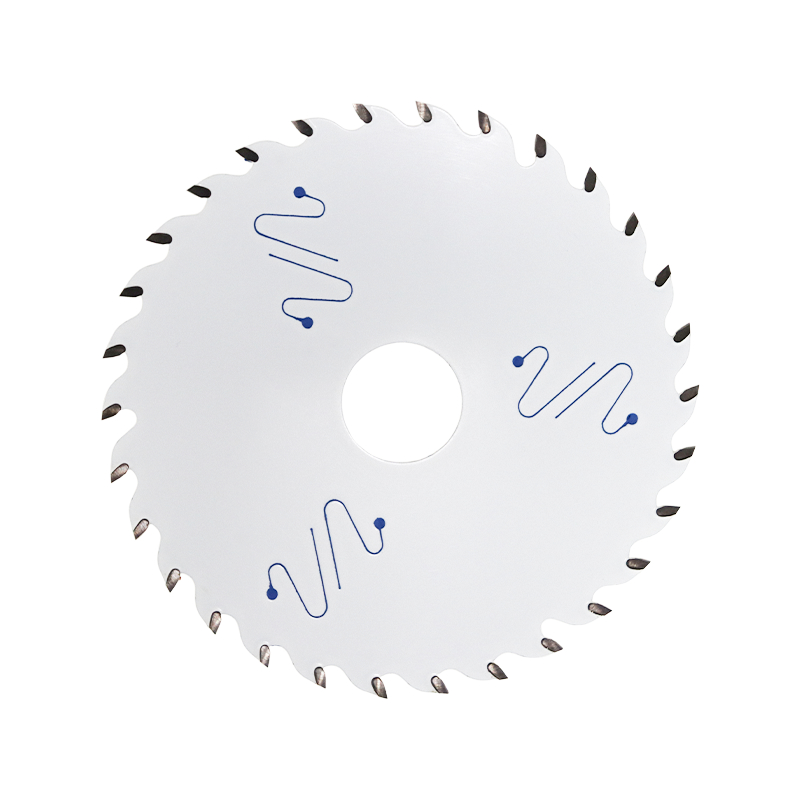

PCD Circular Saw Blades are designed to cut hard materials that would otherwise be difficult to machine. They're made of polycrystalline diamond, a material that matches no other in terms of strength and durability, and they'll last up to 15x longer than a conventional TCT blade.

PCD cutting blades are ideal for cutting materials that are hard to cut, such as concrete, tile, composite board, plastic siding, fiber cement, and wood. They're also more accurate than conventional blades and are available in a wide range of shapes and sizes.

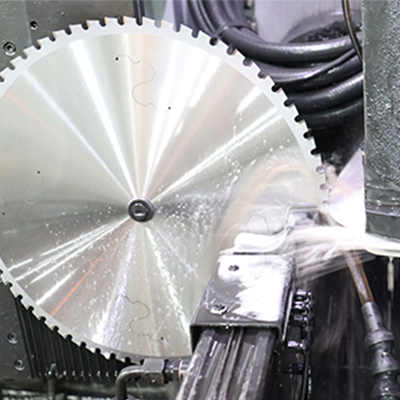

Metal Cutting

A circular saw blade is a key part of any power tool, and it can be used for a wide variety of tasks. It's especially popular for cutting lumber, and it can also be used to cut sheet metal. Choosing the right blade can make a big difference in performance and cost, so it's important to get the right one for your project.

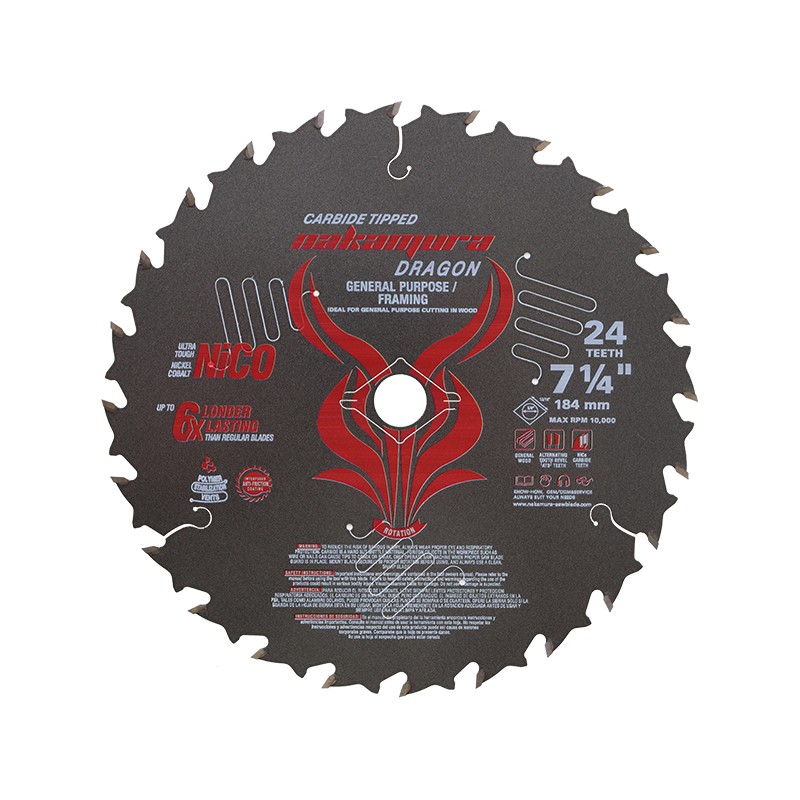

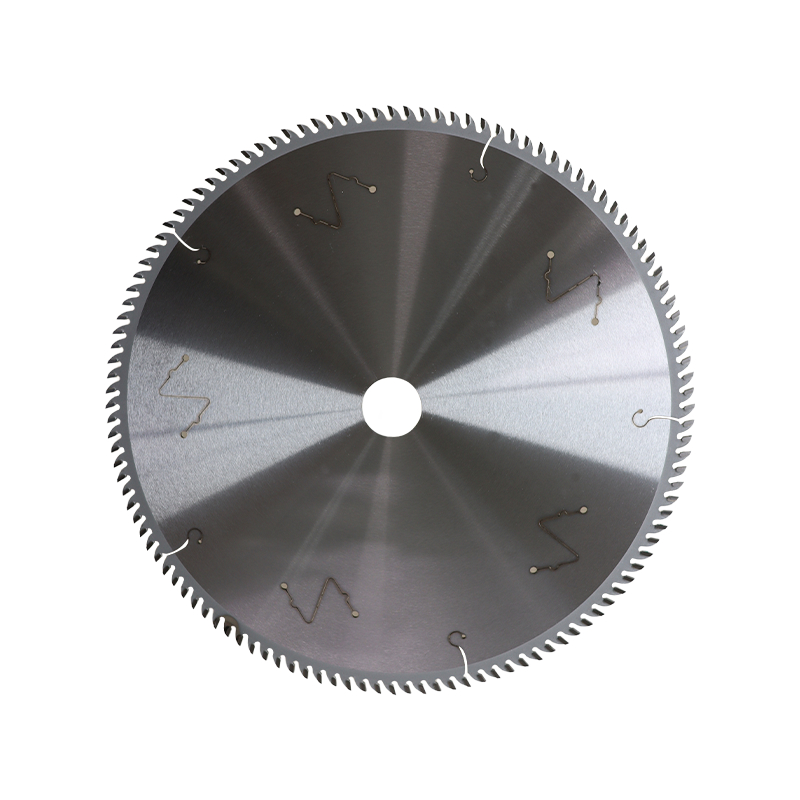

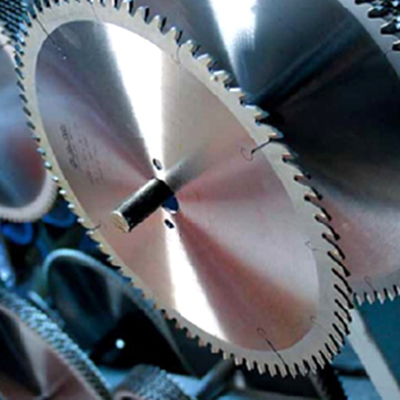

The size and shape of the blade also impact performance. For example, a general-purpose wood-cutting blade can have fewer teeth than a metal-cutting one to remove as much waste from the cut as possible. However, metal-cutting blades often have a higher tooth count to produce smoother, faster cuts.

Other factors, such as the shape of the blade and the material being cut, affect how well it performs. A high-tooth-count blade can shave off more material, but it's more likely to cause binding in the cut. A low-tooth-count blade can create a smoother finish, but it can also wear out more quickly.

Tooth Grind

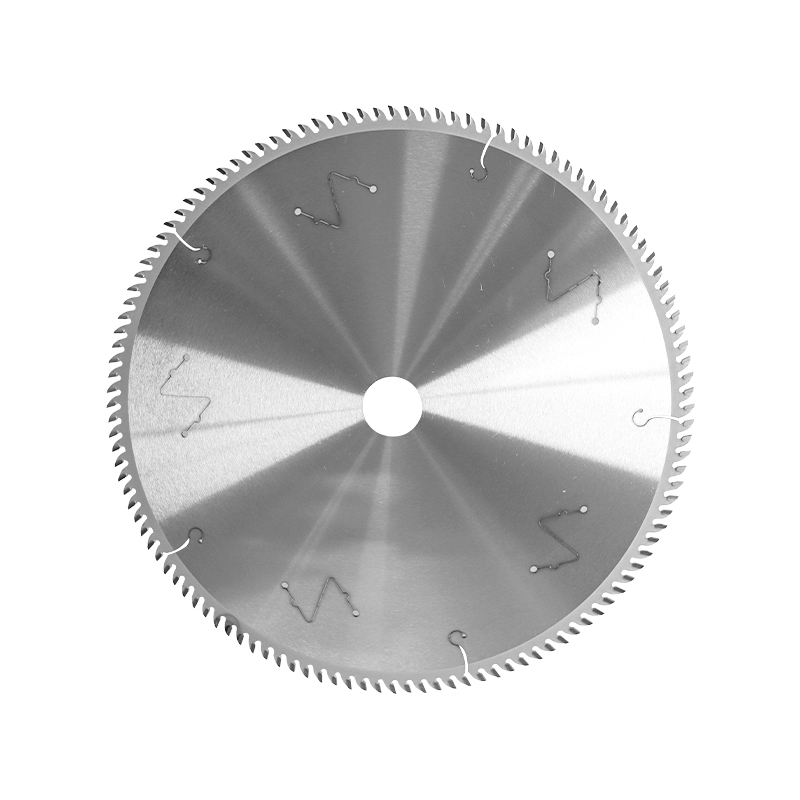

Teeth are shaped to match the cut, and they can be ground in various ways. Flat-top teeth lean forward and are best for ripping soft materials, such as plywood or laminates; alternative top bevel (ATB) teeth have a steeply beveled edge that cuts aggressively with fast feed rates, such as in ripping hardwood. Triple-chip grind (TCG) teeth alternate between a flat "raking" tooth and a higher, trapeze-shaped tooth.

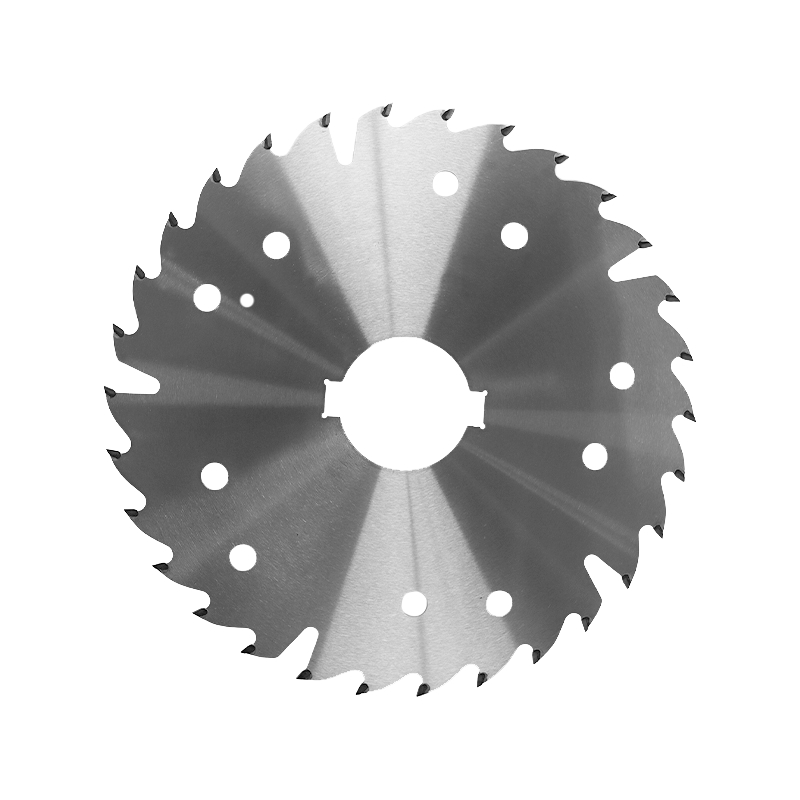

A high-tooth-count blade is more expensive, but it's also less likely to cut poorly or wear out prematurely. The number of teeth on a wood-cutting blade is usually around 24, while a metal-cutting blade can have 60 or more.

Using the wrong blade can be dangerous, so it's important to choose the right one for your job. If you're cutting a material that's prone to warping or bending, consider a blade with expansion slots, which allow the blade to expel its heat before it overheats and causes damage.

If you're cutting an abrasive material, look for blades that have anti-friction coatings to protect against splinters, grit, and other debris. This will extend the life of the blade and help you make more accurate cuts.

The kerf on a blade is designed to remove dust and debris from the cut, so the more ridges in the kerf, the better it'll work. The kerf is also designed to be deep, so the blade can penetrate more material, which means it will cut faster.

ZCDJ-146-153 Sanding Surface Diamond Cutting PCD Circular Saw Blades

Name: Sanding Surface Diamond Cutting PCD Circular Saw Blades

Material: 75Cr1

Chrome plating surface, diameter is 80mm, 100MM, 125MM, 180mm

Teeth: Carbide Teeth (OKE CARBIDE)

Arbor: 20mm, 25.4MM, or customized

English

English 中文简体

中文简体