TCT Saw Blades are a type of circular saw blade that uses tungsten carbide tips

Date:2023-06-15

TCT Saw Blades

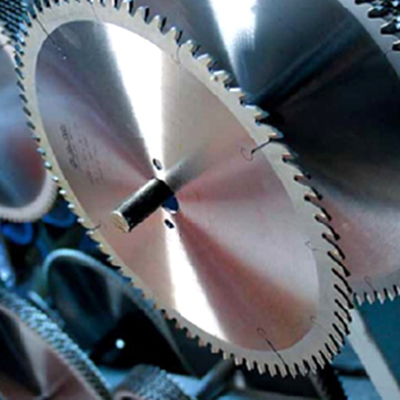

TCT Saw Blades are a type of circular saw blade that uses tungsten carbide tips. These tips provide even edge wear and make them ideal for heavy-duty applications. They are used to cut pipe, tube, profile, rail, nickel, zirconium, cobalt, and titanium-based metals. They also work well with wood and plastics.

Choosing the Right Saw Blade For Your Job

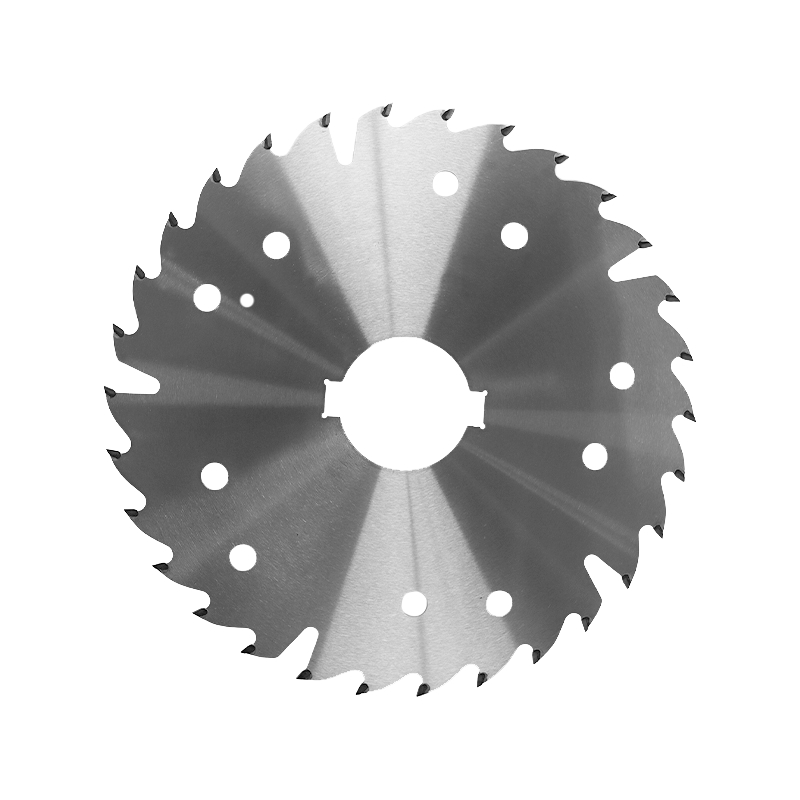

The type of material you’re cutting will determine which saw blade you use. Some materials, such as wood or non-ferrous metals, require blades with fewer teeth to get a clean cut. Other materials, such as metal tubing or pipes, require blades with a greater kerf, or width of the teeth.

Generally, the more teeth a blade has, the faster it can cut; however, the kerf width and number of teeth will also play a role in how clean the cut is.

TCT Blades for Cutting Metal

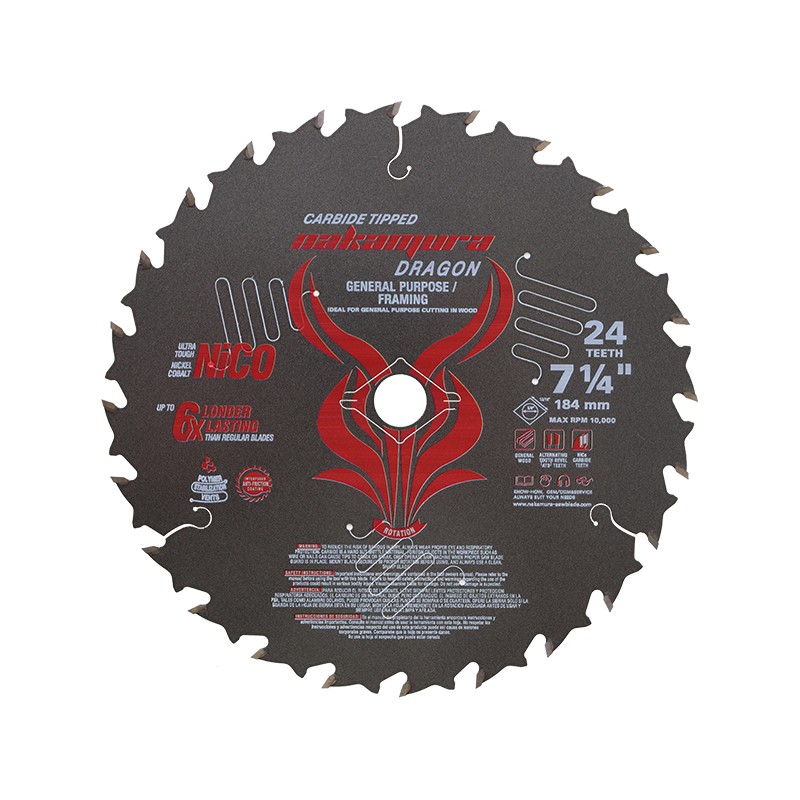

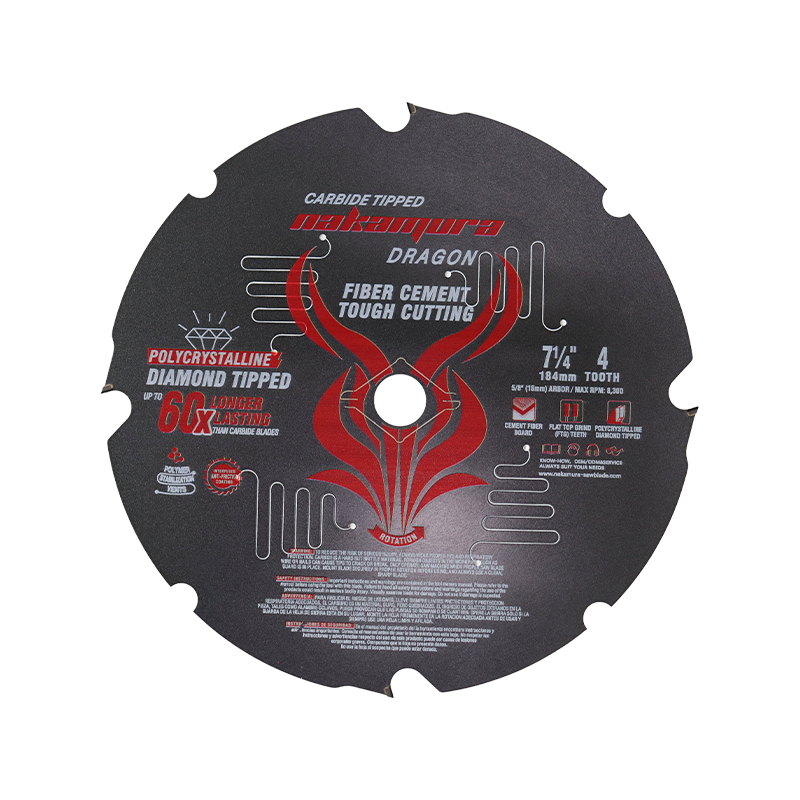

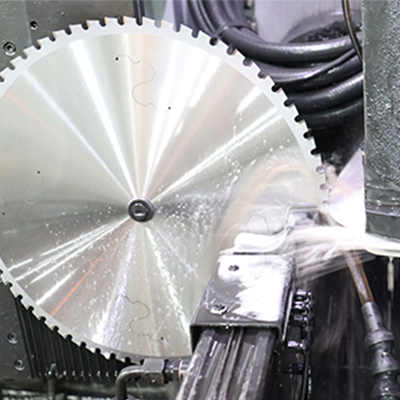

Tungsten carbide-tipped (TCT) circular saw blades are made from a chemical compound that is two times stiffer than steel. They are also more resistant to heat and shock, so they can be used for longer periods of time.

They are available in a variety of tooth shapes, carbide grades, and coatings that can temper to last for a lifetime. They are especially useful for ripping, crosscutting, and slicing, and their tips can be replaced in case of damage.

Their high torque and power make them suitable for cutting metal rods, tubes, pipes, rails, and other heavy-duty materials. They are also commonly used to cut non-ferrous metals, including aluminum, copper, and steel.

When it comes to cutting hard materials, such as masonry or concrete, TCT blades are better than solid HSS saw blades because they offer more control over the blade’s feed rate and cutting speed. They also don’t produce as much dust or sparks, so they are safer to use than other types of saw blades.

They are also available in a variety of blade sizes, including a range of angles that can help you optimize your cuts. They can also be re-sharpened to keep them sharp for longer periods of time.

Using an Old Saw Blade

If you’ve been putting off purchasing a circular saw for your home or workshop, the first thing you need to do is find out whether it will be capable of making the job easier and safer for you. It’s also important to understand how to replace the blade when it needs to be replaced.

It’s a lot of hassle to make additional cuts with a dull saw blade, so replacing it as soon as you notice any signs of wear is a good idea. It can save you a lot of money and trouble in the long run, not to mention make your tool easier to use and more comfortable for you.

When it comes to selecting a blade, there are several factors to consider, including the type of material you’re cutting and the size of your project. You should also consider the type of grit and the tooth geometry to find the best blade for your particular application.

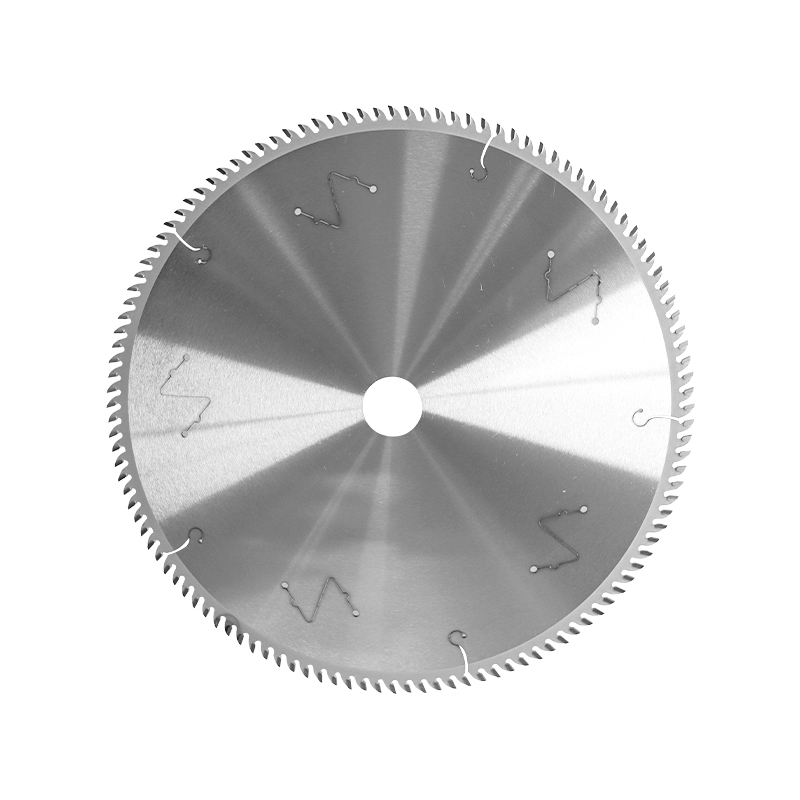

ZCDJ-034 Multifunctional Cutting Multi-Purpose Circular Saw Blades

ZCDJ-034 Multifunctional Cutting Multi-Purpose Circular Saw Blades

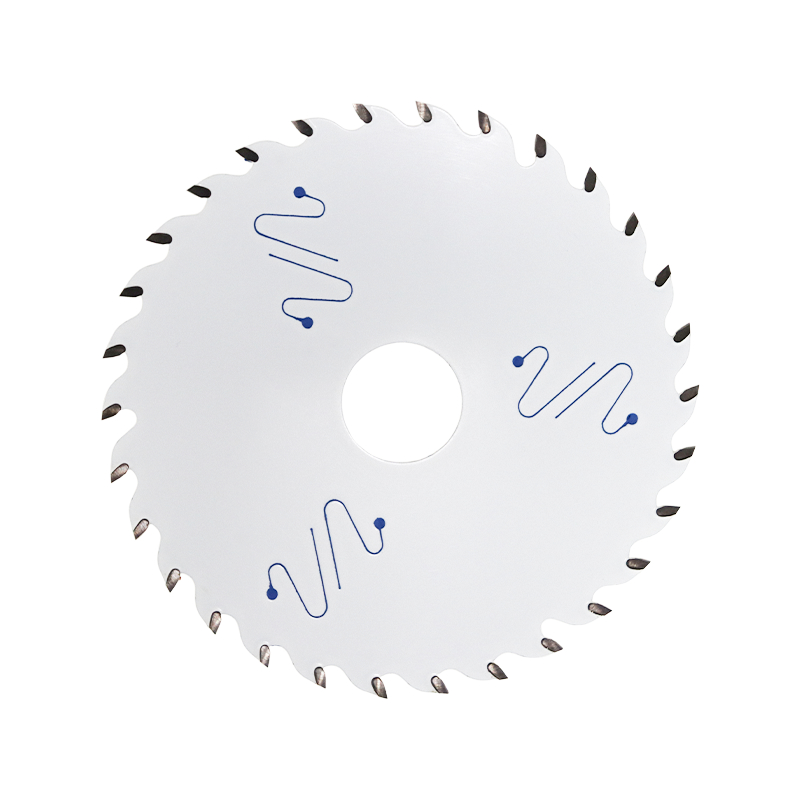

Name: Multifunctional Cutting Multi-Purpose Circular Saw Blades

Material: 75Cr1

Teflon surface, diameter is 184mm

Teeth: Carbide Teeth (OKE CARBIDE)

Arbor: 15.88mm or customized

English

English 中文简体

中文简体