What You Should Know About Metal Saw Blades

Date:2023-05-17

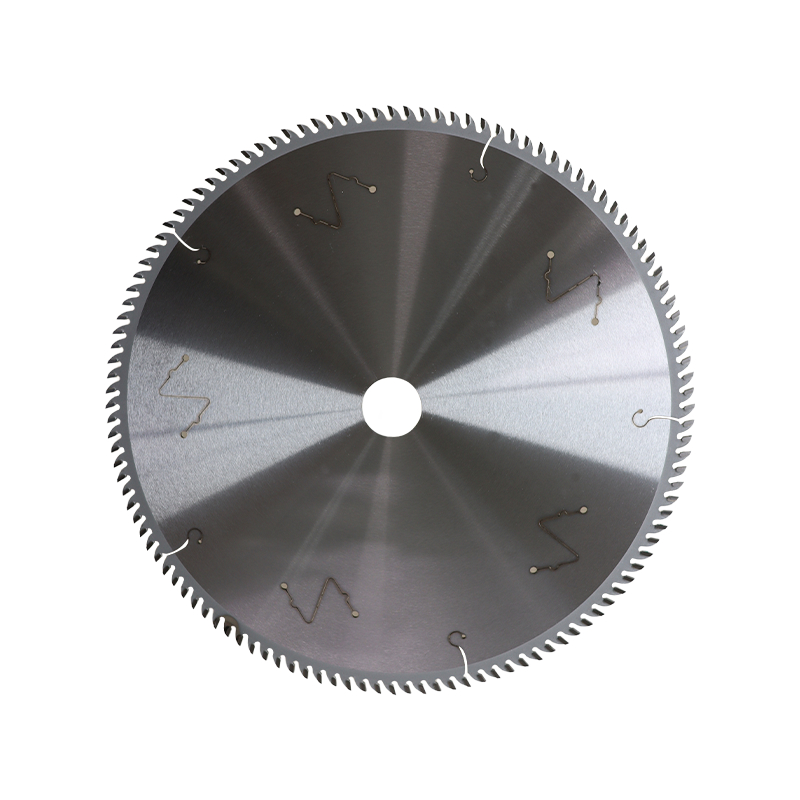

Steel is a hard and durable metal that is used to make many tools, including circular saw blades. They can be made of high-carbon steel or other types of materials to suit your needs.

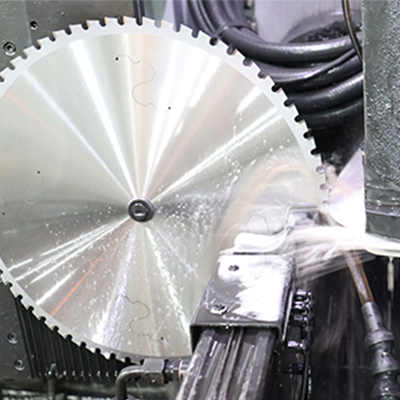

The production process of a metal cutting circular blade involves several stages, starting with the heating and cooling of the steel. This is done to get the desired shape and finish. The heat treatment procedure also strengthens the steel and helps prevent cracks.

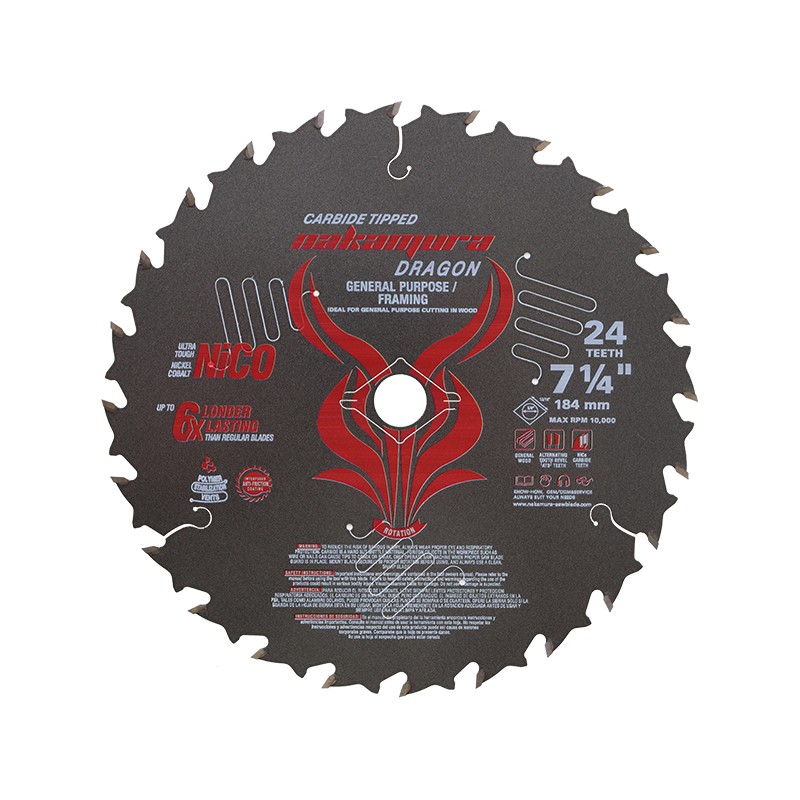

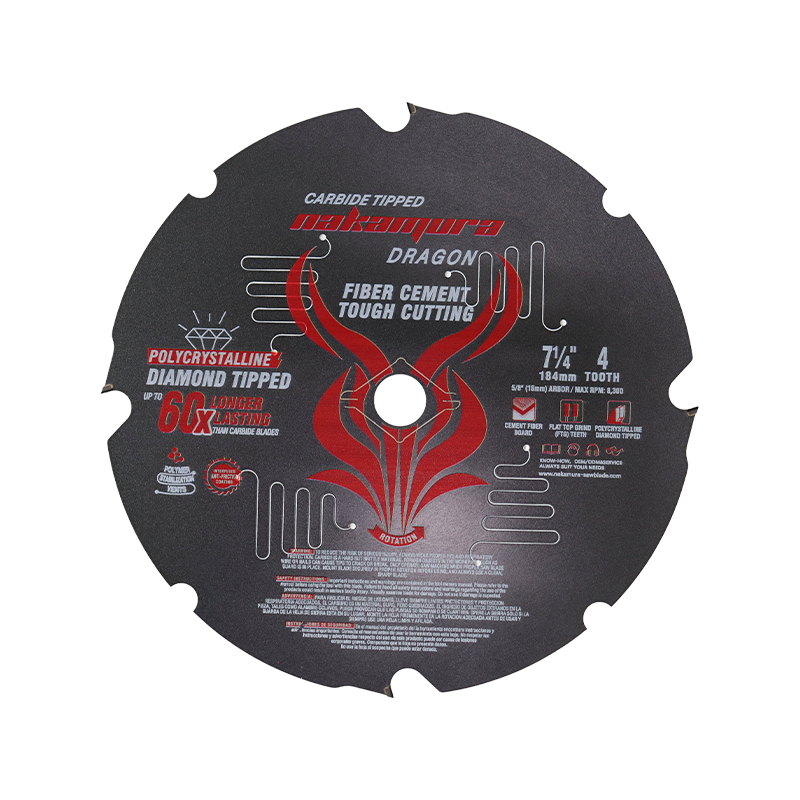

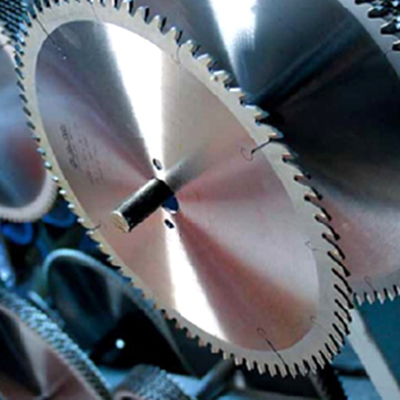

Carbide Tipped Teeth

A metal cutting blade will have a number of different teeth that are tipped with a type of ceramic-carbide material called Cermet. This provides excellent cutting performance, making it ideal for both ferrous and nonferrous materials.

These blades can be used to cut a variety of materials, from thin sheet metal to stainless steel, aluminum, and other types of metals. They will have a number of different tooth pitches to match the thickness of the material you're cutting.

They are a great choice for metal work, especially if you have a band saw or chop saw that can produce high blade speeds. This allows the blade to make smooth cuts without damaging the material being cut.

There are a few things you should consider before buying a metal-cutting circular blade, including the following:

The Hook Angle

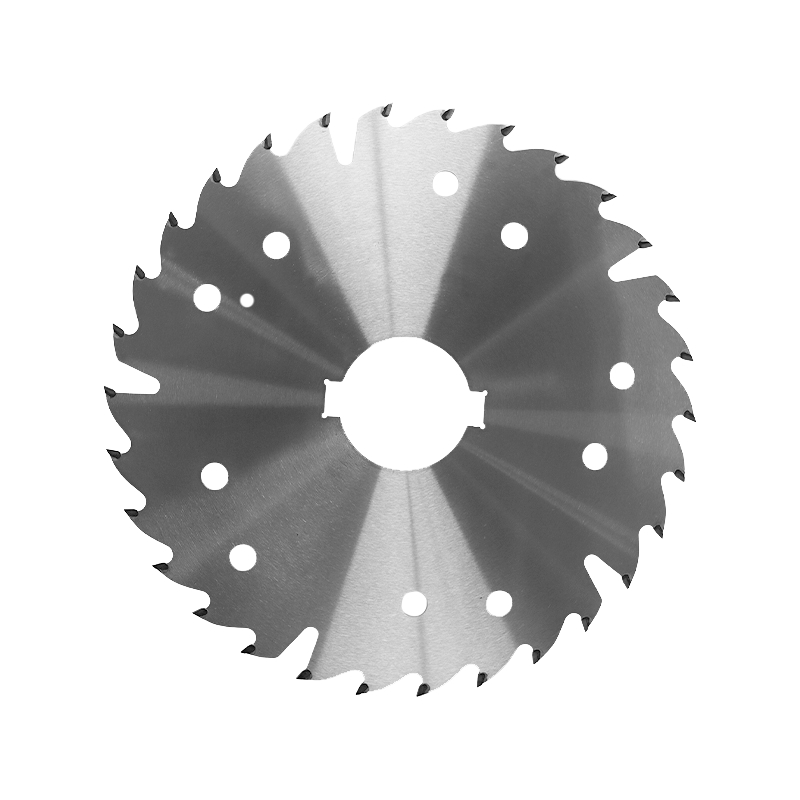

A hook angle or claw shape is a notch at the bottom of the tooth that helps hold the material in place as it cuts. This can be positive, meaning the blade lays flat against the material, or negative, which is more aggressive and slopes away from the material.

The hook angle is especially important when cutting softer materials, such as wood. This provides a better grip on the material being cut and reduces kickback.

If you're working with a band saw or a chop saw, this may be important to you as it will help you to make smoother cuts than a standard abrasive blade would. This will save you time and money on your projects and ensure that you're getting the most out of your equipment.

Another factor that you should consider is the number of teeth per inch (tpi). Generally, more teeth per inch mean that a blade will be able to cut harder materials like steel.

Lastly, it is also important to consider the type of material you'll be cutting. Typically, ferrous metals will require a steel cutting blade, while nonferrous materials will require a carbide cutting blade.

The most important thing you should do is to choose the right tool and blade for the job at hand. This will help you to get the best results possible and will ensure that you're safe while you're working. Always wear personal protective equipment (PPE) when working with a blade, including gloves and safety glasses to protect your eyes from sparks or burns.

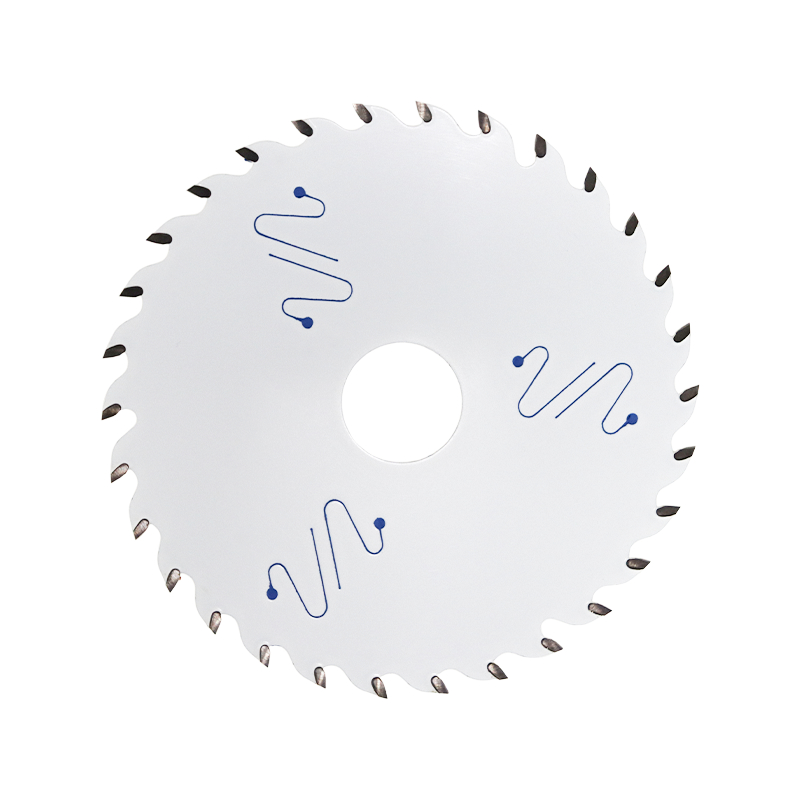

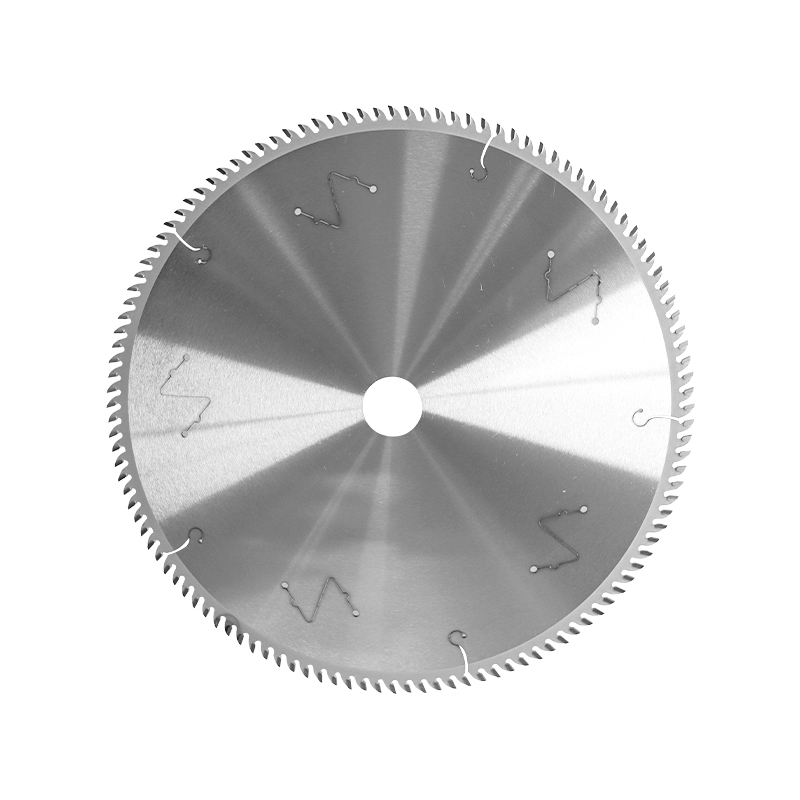

ZCDJ-027 Acrylic Cutting Circular Tungsten Carbide Tipped Round Saw

Nakamura Logo or customization.

Teflon Surface, DIAMETER is 305mm.

Package is white inner box or blister or sleeve tube and plastic bage.

Material: 75Cr1.

Teeth: 100Teeth(OKE Brand).

Arbor:15.88mm, 20mm, 25.4mm, 30mm or customized.

Application: Acrylic, Wood.

English

English 中文简体

中文简体